Small hole gauges, next bore measuring purchase after telescoping gauges imo. My view is a quality set is preferred as like telescoping gauges, there is feel involved. I've found Starrett, Lufkin, Mitutoyo, PEC, Suzuki and Helios are all excellent but like most things buy used as they can be pricey.

Brown & Sharpe has an interesting version of this that used two balls instead of the split stem. I have a set and they go down to a 1/16 which is sometimes handy

For even smaller, a 0.010" - 0.060 pin gauge set is handy

Using small hole gauges should be accurate in use to a thou or better. Do a few iterations until you get consistent results.

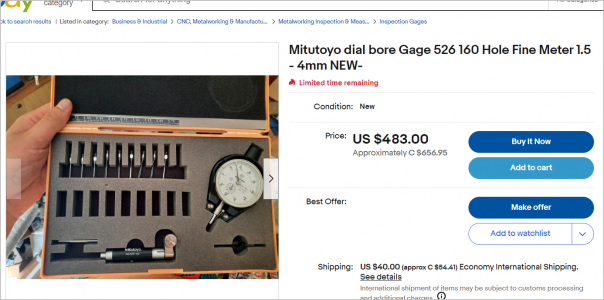

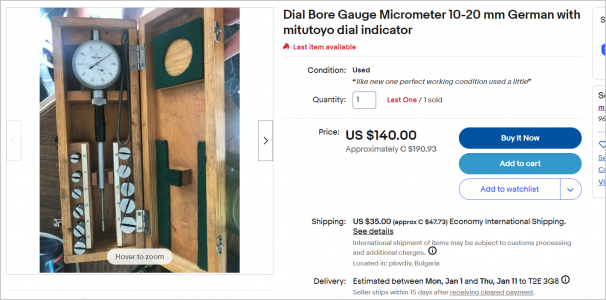

Dial bore gages are direct reading, pretty much accurate to whatever dial is mounted. Tenths is common.

I've got them in tenths and microns. A micron is damn near impossible to hit, just the variance in surface finish (even when grinding) seems to create tiny variances that will flicker the needle. otoh, if less than tenths, not a lot of advantages over just using telescoping gauges.

DBG probably the most accurate way to measure a bore, but not really direct the way a mic is in that you have either zero them with a mic (or gauge block stack) or use a mic to measure them after. i.e. measuring across the bore gauge anvils or zero in the indicator is slightly fidgety, I do it between anvils of a mic held in stand that has be set with gauge blocks. There is a setting rig that would make it easier, but I don't have one, and I concede ring gauges might make them pretty much direct reading.

I picked up a set of borematic gauges awhile ago....now that is luxury! Just need a few more setting rings and that'll be the go-to.

My conclusion is bores are always a challenge to measure accurately and I've collected a ton of stuff to make the job easier.....but.....98% of the time its reach for the small hole gauges or telescoping gauges. The other stuff more comes into play doing really fussy stuff, like fitting a TS quill to a lapped bore or bores for expensive match bearings etc. 10ths fits that just don't confront us with most stuff we do.