Hello gang.

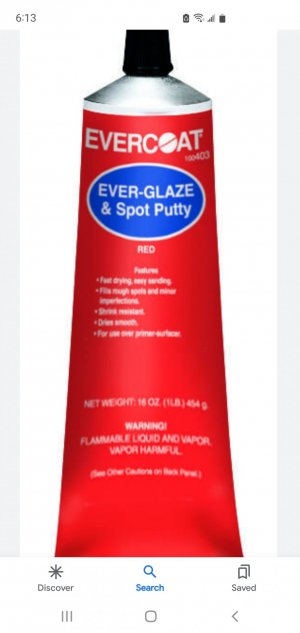

Looking into reasonable alternative to high build primer (AKA sandable primer, AKA filer primer). Better be epoxy. I checked local stores, automotive suppliers and body shops, Amazon... Price is too high for my budget.

I am going to rebuild/repaint my newly acquired milling machine.

This what I did.

Option one - epoxy resin with solid filler, diluted with acetone to pass trough spray nozzle. Not really chip either, messy, with very limited work time and fear to clog spray gun.

Option two - regular rustoleum primer with 20% solids (either talkum or chalk) also diluted for spraying. Not as strong as epoxy, though cheap and less intimidating.

Are there any other options?

Thanks.

Looking into reasonable alternative to high build primer (AKA sandable primer, AKA filer primer). Better be epoxy. I checked local stores, automotive suppliers and body shops, Amazon... Price is too high for my budget.

I am going to rebuild/repaint my newly acquired milling machine.

This what I did.

Option one - epoxy resin with solid filler, diluted with acetone to pass trough spray nozzle. Not really chip either, messy, with very limited work time and fear to clog spray gun.

Option two - regular rustoleum primer with 20% solids (either talkum or chalk) also diluted for spraying. Not as strong as epoxy, though cheap and less intimidating.

Are there any other options?

Thanks.