JuryriggedSean

New Member

Hello from Victoria BC.

Just getting into this fascinating world. I started out by making knives by hand, but got tired of all the file work. I then built my first machine as I wanted a belt grinder to make easier. I made a decent little guy out of salvaged and free materials.

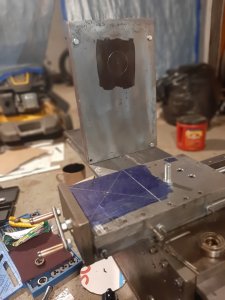

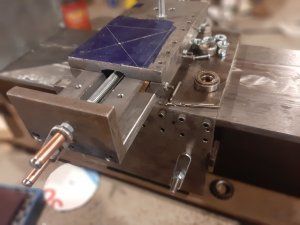

What followed was a series of little projects that led me to my possibly foolhardy goal of building my own lathe. I've got a working bed, ways, and carriage and cross slide. Next on the list is building the headstock and spindle to get it functioning so I can use the lathe to build the rest of my lathe.

I've used your site previously as its been useful in sourcing material and figured I should join up and participate.

Just getting into this fascinating world. I started out by making knives by hand, but got tired of all the file work. I then built my first machine as I wanted a belt grinder to make easier. I made a decent little guy out of salvaged and free materials.

What followed was a series of little projects that led me to my possibly foolhardy goal of building my own lathe. I've got a working bed, ways, and carriage and cross slide. Next on the list is building the headstock and spindle to get it functioning so I can use the lathe to build the rest of my lathe.

I've used your site previously as its been useful in sourcing material and figured I should join up and participate.