Rauce

Ultra Member

Hi! Found this place while looking up various options for new lathes.

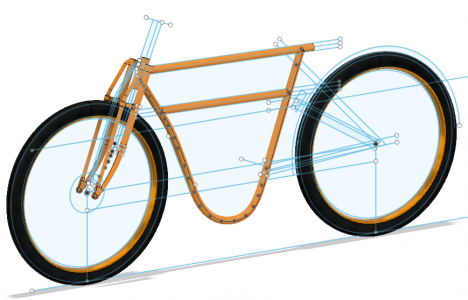

I live in Hamilton and got into metalworking through cycling. I’ve always liked doing things myself and 6 or 7 years ago while working at a bike shop I decided I should just build my own frames. Machine tools aren’t required for that but they are handy so with the help of a machinist friend I got into machining as well.

After getting laid off at my old office job 3 years ago I decided to convert my metalworking hobby into a career and now I’m nearing the end of my Millwright apprenticeship.

Here is a picture of my current machines at home from just over a year ago. The Excello is fully reassembled and running now. The lathe is a Churchill Cub MkIII 13x24.

I live in Hamilton and got into metalworking through cycling. I’ve always liked doing things myself and 6 or 7 years ago while working at a bike shop I decided I should just build my own frames. Machine tools aren’t required for that but they are handy so with the help of a machinist friend I got into machining as well.

After getting laid off at my old office job 3 years ago I decided to convert my metalworking hobby into a career and now I’m nearing the end of my Millwright apprenticeship.

Here is a picture of my current machines at home from just over a year ago. The Excello is fully reassembled and running now. The lathe is a Churchill Cub MkIII 13x24.