Hi all:

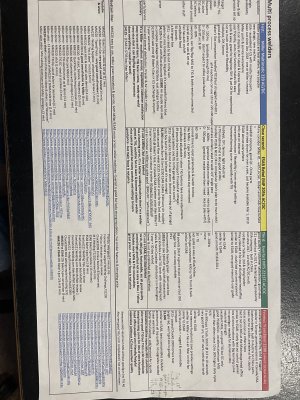

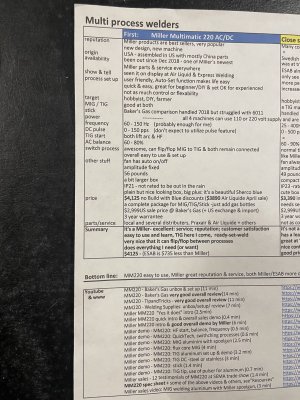

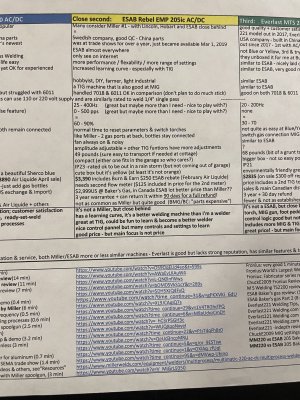

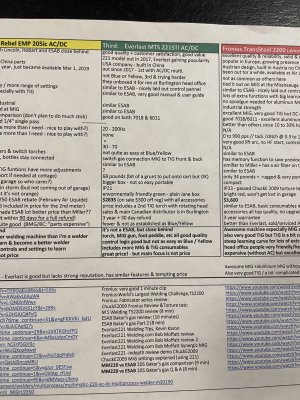

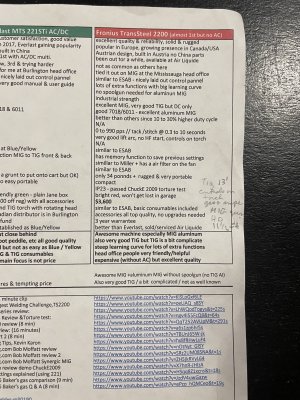

New to the forum. Looking for some recommendations on what to buy. Would like to be able to weld Metal/Steel, Aluminum and Stainless. Mainly for fixing broken things but also to do some small projects. Don't think I will go past 1/4" thickness very often. Took stick welding (80 hours) and gas welding/cutting torch (80 hours) courses about 40 years ago in Germany but haven't done much welding in the last 10 years. Contemplating if I should go for gas MIG or TIG.

On some other forums I saw the recommendation to get a 240 Volt (or 110/240 Volt) stick/TIG machine. Uncertain if I will use it very often so also looking for low cost of ownership. Don't have any experience how expensive it is to maintain a gas bottle (certifications, etc.). Want to spend as little as possible but willing to spend as much as necessary to get a good solution. Where to go in Calgary for welding machines and supply? Much appreciated!

Thanks,

Gunter

New to the forum. Looking for some recommendations on what to buy. Would like to be able to weld Metal/Steel, Aluminum and Stainless. Mainly for fixing broken things but also to do some small projects. Don't think I will go past 1/4" thickness very often. Took stick welding (80 hours) and gas welding/cutting torch (80 hours) courses about 40 years ago in Germany but haven't done much welding in the last 10 years. Contemplating if I should go for gas MIG or TIG.

On some other forums I saw the recommendation to get a 240 Volt (or 110/240 Volt) stick/TIG machine. Uncertain if I will use it very often so also looking for low cost of ownership. Don't have any experience how expensive it is to maintain a gas bottle (certifications, etc.). Want to spend as little as possible but willing to spend as much as necessary to get a good solution. Where to go in Calgary for welding machines and supply? Much appreciated!

Thanks,

Gunter