Hi, I recently purchased a Harrison M300 with a taper attachment. Unfortunately it is missing the rod that connects the ways clamp to the taper attachment. If anyone has this lathe with this setup it would be immensely helpful I could get a length for this rod as it looks like I will have to reproduce it.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Harrison M300 Taper Attachment

- Thread starter S.Heron

- Start date

If it works the same as others do, it just needs to be as long as the taper length. Longer will not hurt, but could affect longitudinal buckling rigidity very marginally.

If I were you, I'd make it as long as needed plus a few inches, but also with a bigger OD in the center. This would work beautiful.

If I were you, I'd make it as long as needed plus a few inches, but also with a bigger OD in the center. This would work beautiful.

Yep. That's the beauty of it, the length is pretty much completely not critical.If it works the same as others do, it just needs to be as long as the taper length. Longer will not hurt, but could affect longitudinal buckling rigidity very marginally.

If I were you, I'd make it as long as needed plus a few inches, but also with a bigger OD in the center. This would work beautiful.

If you feel the absolute 'need' to get it pretty close to factory, find a photo of the set-up in the manual or online, and walk off the distance with a set of dividers, using another feature that is handy, for scale, say, a knob or the width of the taper attachment itself.

Thanks for the help! Upnorth

Susquatch while a larger diameter bar sounds like a good idea I believe the attachment point a single M8 bolt in shear would be the source of any loss of rigidity. Sure one could drill and tap it to a larger size but I don't think I would feel great about that mod

Trev that's a great idea I will use in the future.

To use the taper attachment are there any modifications that one has to do besides install the clamp to the ways?

Susquatch while a larger diameter bar sounds like a good idea I believe the attachment point a single M8 bolt in shear would be the source of any loss of rigidity. Sure one could drill and tap it to a larger size but I don't think I would feel great about that mod

Trev that's a great idea I will use in the future.

To use the taper attachment are there any modifications that one has to do besides install the clamp to the ways?

No just attach and use. If you ever need to order parts keep in mind that the saddle is non standard now. There is a special part in there so it moves to accommodate the taper attachment. I think it's described in the manual.Thanks for the help! Upnorth

Susquatch while a larger diameter bar sounds like a good idea I believe the attachment point a single M8 bolt in shear would be the source of any loss of rigidity. Sure one could drill and tap it to a larger size but I don't think I would feel great about that mod

Trev that's a great idea I will use in the future.

To use the taper attachment are there any modifications that one has to do besides install the clamp to the ways?

Susquatch while a larger diameter bar sounds like a good idea I believe the attachment point a single M8 bolt in shear would be the source of any loss of rigidity. Sure one could drill and tap it to a larger size but I don't think I would feel great about that mod

You are always welcome to seek additional engineering input from others.

A larger diameter bar will help reduce compression buckling which will improve rigidity in the taper cutting process. Since it is only to stiffen the bar, the end attachments of the bar can be turned down to be consistent with the original design size so as not to compromise the attachment. But I wouldn't worry about the screw anchor. Even a much stiffer bar will buckle long before the screw shears.

Keep in mind that bending and failure are two different things. Everything bends under a force. It isn't if, it's only how much. That's why a bigger bar is a good thing.

Lastly, while I'm certain that it will bend, I'm not at all certain that it matters a whole lot. The bar that came with my taper attachment is only 1/4 inches in diameter. It will get replaced by something more like the one @Upnorth has - 3/4 inch sounds much more reasonable for this application to me. My original comment recommending a bigger bar was in the context of a 1/4 inch bar like mine before I even knew that Upnorth's was so much bigger. Bigger is better in this case.

I am trying to picture doing a taper on the lathe, with the bar being compressed, rather than being in tension, and I don't think I have ever done one, which kinda makes it a moot point to be worried about the bar flexing, I kinda think.

Loads on that bar are pretty mild, though, and I doubt it is going to be a breakdown kind of risk.

Loads on that bar are pretty mild, though, and I doubt it is going to be a breakdown kind of risk.

RobinHood

Ultra Member

When you are feeding away from the HS, the bar would be in compression.I am trying to picture doing a taper on the lathe, with the bar being compressed, rather than being in tension,

Well, yeah, obviously.When you are feeding away from the HS, the bar would be in compression.

But I cannot ever recall doing a taper that way. Seems to have always been set up doing the feeding towards the headstock. <shrug> Dunno why, just seemed to work out that way. Spent a fair few hours making Morse Tapers and teaching other Technicians how to set up a taper, using the DRO travels to very good effect once backlash is accounted for...

Reality is that you will be placing that bar in compression (what little it gets) after every cut, when you return to your starting position, if you are not running away from the headstock, anyways. The loads on it are NOT very high, by the time that the saddle starts sliding along the taper bar.

The loads on it are NOT very high, by the time that the saddle starts sliding along the taper bar.

This thread probably isnt the best place to discuss such things. The question for you Trev (for all our benefit) is would you rather have a 1/4 bar or a 3/4 bar for this application.......

I think we can all agree that the loads are not high. Certainly not high enough to shear anchor bolts or permanently deform the anchor arm. But they are not zero. Therefore the bar will bend. It's not if, it's only how much. Personally, I doubt that the friction in the slide is nearly as great as the longitudinal cutting forces - no matter which direction they are. However, it doesn't matter because they are additive and ALL of them combined have to be reacted by the bar.

I'd have to do some math and make a bunch of assumptions, but my instincts tell me that the forces are enough to matter when cutting across the length of the taper anchored by a piano wire with various cutting depths as the final dimension is approached. Maybe one day I'll actually do the math and some tests. But first I have a wrestling match with Grizzly. (no word yet), and then I need to figure out how to fit my planned DRO inside the Taper and Cross Slide, and then actually install everything.

Like you, I usually cut my tapers small to big toward the headstock - usually because of my choice of operations order. But not discussed here is an assessment of making cuts in both directions....... I've done that before using the compound. It would be interesting to see how it would pan out using a taper attachment!

For the benefit of the OP, let me ask you, if you were starting fresh to make a missing anchor bar, how big would it be?

Spoiler - I'll tell you right now that my bar will be upgraded to at least 3/4"! Maybe bigger! LOL!

In truth, I'd use whatever the factory anchor was fitted out to use. And not lose any sleep over it, either.This thread probably isnt the best place to discuss such things. The question for you Trev (for all our benefit) is would you rather have a 1/4 bar or a 3/4 bar for this application.......

I think we can all agree that the loads are not high. Certainly not high enough to shear anchor bolts or permanently deform the anchor arm. But they are not zero. Therefore the bar will bend. It's not if, it's only how much. Personally, I doubt that the friction in the slide is nearly as great as the longitudinal cutting forces - no matter which direction they are. However, it doesn't matter because they are additive and ALL of them combined have to be reacted by the bar.

I'd have to do some math and make a bunch of assumptions, but my instincts tell me that the forces are enough to matter when cutting across the length of the taper anchored by a piano wire with various cutting depths as the final dimension is approached. Maybe one day I'll actually do the math and some tests. But first I have a wrestling match with Grizzly. (no word yet), and then I need to figure out how to fit my planned DRO inside the Taper and Cross Slide, and then actually install everything.

Like you, I usually cut my tapers small to big toward the headstock - usually because of my choice of operations order. But not discussed here is an assessment of making cuts in both directions....... I've done that before using the compound. It would be interesting to see how it would pan out using a taper attachment!

For the benefit of the OP, let me ask you, if you were starting fresh to make a missing anchor bar, how big would it be?

Spoiler - I'll tell you right now that my bar will be upgraded to at least 3/4"! Maybe bigger! LOL!

Worrying overlong, about things that 'might' be a problem, before actually seeing if maybe the folks that made it, did so well enough to work without issue, stands in the way of getting anything actually done.

By memory, My Colchester has a round bar that goes through a round hole on the anchor point, that can be adjusted to give various positions as required for clearance, etc. I would bet that the anchor point where it clamped to either the bed, or the rod itself, a far more likely point to fail, than the rod itself ever bending.

I would bet that the anchor point where it clamped to either the bed, or the rod itself, a far more likely point to fail, than the rod itself ever bending.

Your on! This might be fun! Let's agree on the terms next!

My problem is trying to imagine a set-up, so poor, as to enable the application of enough force to cause problems, without it being essentially a crash condition. (and yeah, have seen more than a few of those!) Failure to properly account for the travels needed, IMO, does not actually point out any supposed weakness, of the smaller diameter rod.Your on! This might be fun! Let's agree on the terms next!

The sheer amount of mechanical advantage that operates a taper attachment, to make it work, seems to me, to be pretty well within the collapse limits of even the 1/4 rod you spoke of, that came with your taper attachment, to handle.

Which essentially leaves just a plain poorly done set-up, as any likely culprit for any form of failure. Essentially, 'building it bigger' would simply move the failure point to a more expensive part, I think.

While I agree that a larger diameter rod is always going to out-perform in a comprehensive testing regime, say, applying pressure with any form of press, there is a point where it is moot, if the system cannot under normal circumstances, apply that level of pressure without 'other' failures. Most of those, "Operator"!

My problem is trying to imagine a set-up, so poor, as to enable the application of enough force to cause problems, without it being essentially a crash condition. (and yeah, have seen more than a few of those!) Failure to properly account for the travels needed, IMO, does not actually point out any supposed weakness, of the smaller diameter rod.

You are no fun Trev....

I suppose we won't be able to do more than agree to disagree then.

I'll make a bigger one like @Upnorth and report back later.

In tension or compression, a rod is either supported at one end or both - or somewhere else. The one end supported loads are generally 4 times the both end supported ones - for moment reactions from transverse load. But the other than more deflection under the cutter, I fail to see the problem. It is what it is

If the load is a compressive one, there is the additional risk of lateral tortional bucking. Almost non-existent if it is a both ends supported load, the slenderness ratio and the radius of gyration are the standard terms to do the math

If the load is a compressive one, there is the additional risk of lateral tortional bucking. Almost non-existent if it is a both ends supported load, the slenderness ratio and the radius of gyration are the standard terms to do the math

it is unclear to me what this part looks like, but it seems obvious that the key point is slenderness ratio

I was wondering if you would show up here.....

Basically, it's a long rod about 22" long that is locked to a bed anchor bracket at one end and the taper base plate at the other. It's purpose is to stop the plate from moving as the cross slide traverses back and forth on the taper attachment way.

The taper base plate basically hangs from a rear extension of the crosslide and the cross slide moves front to rear following a taper guide on the plate.

My rod is about 1/4" in diameter and @Upnorth's is about 3/4 inches in diameter.

Mine is prolly adequate but its a weak link in the system. I can see no reason not to upgrade it to a 3/4 inch bar.

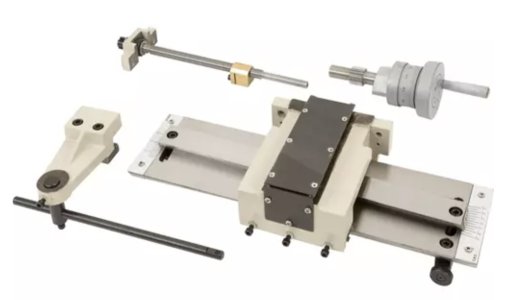

I have not done a buckling analysis. But my guts tell me that there will be a huge difference between 3/4 and 1/4, and further that shearing of the anchor screws is a non-issue. Here is a rendering of the parts:

The large beige block screws to the back of the saddle. The bottom plate is fixed in relation to the ways by the anchor bracket and the subject bar at the bottom left of the photo. Internally, there is a follow-block inside the large block that follows the smaller adjustable taper plate to move the rear anchor of the cross-slide leadscrew in and out.

To visualize the concern, I already suggested substituting the rod with a piano wire. Doing so allows anyone to see the problem. As the slenderness ratio improves with fatter rods, the assembly gets stiffer and stiffer.

Doing the math wouldn't be difficult if we knew the loads. I don't. That would require testing. Therefore about all I can say for now is that piano wire would surely buckle, a 1/4 rod might or might not be a problem depending on your definition of a peoblem, and a 3/4 inch rod would be a safe bet.

The OP @S.Heron really just wanted to know what size of rod to use, and I suggested making it bigger than mine because the one on mine looked too small to me. When I saw how much fatter and shorter @Upnorth's was for roughly the same size lathe, it somewhat vindicated my concerns.

Normally, I wouldn't get overly concerned about such things, but I'm particularly sensitive to the design and manufacturing issues of the taper attachment I just bought. It's VERY disappointing so far.

Post in thread 'Is Taper Attachment worth it?' https://canadianhobbymetalworkers.com/threads/is-taper-attachment-worth-it.8860/post-156856