Tom O

Ultra Member

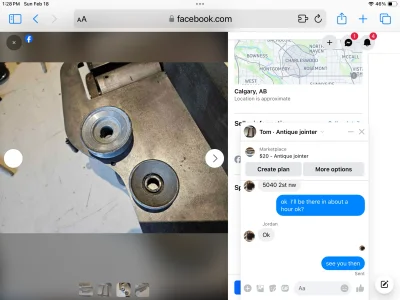

I don’t really need this but the thought is it will be handy with draft angle’s for casting. It’s a little one around 2 or so feet long but I’m not sure how the motor attaches or the hp required any ideas?

The guard will be no problem to make it was $50 originally but marked down to $20 I couldn’t say no!

The guard will be no problem to make it was $50 originally but marked down to $20 I couldn’t say no!