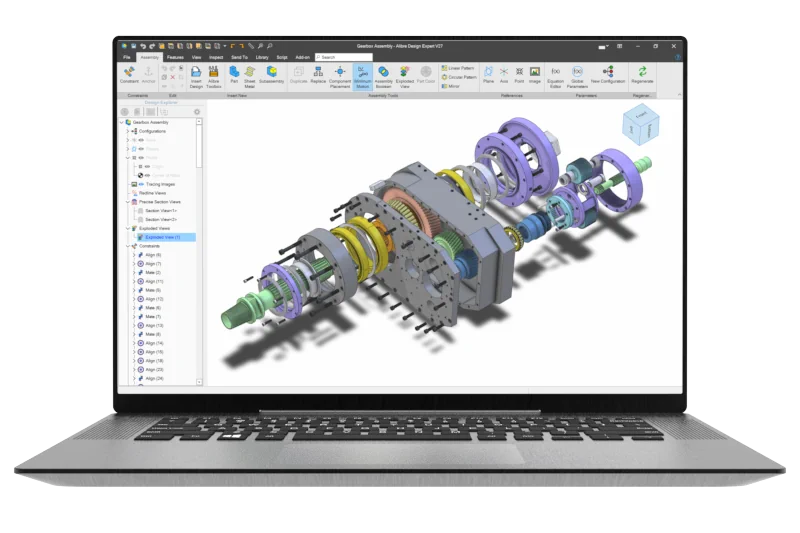

Hey everyone, after some suggestions I was curious about FreeCAD and if it was any easier to use than the last time I tried it a few years ago. So, I got the latest version and installed it. Still not quite getting the hang of parts of it but I think I'm just too used to Fusion and Alibre Atom and need to learn this one's idiosyncrasies too. I suppose one of my biggest concern is that at some point I might not have access to Fusion and need a Plan B or C.

As I have just gotten my first 3D printer, and wish to use it to fiddle with making gears in the not to distant future, I figured to try modeling a gear in FreeCAD but darned if I wasn't having trouble figuring out where that function is found. I know how to make various gears in Fusion as there are scripts readily available with dialog boxes to input parameters but all I've found so far on the FreeCAD forums is some Python code snippets. I have never learned how to program using Python, and while I'm always up for learning new stuff my hobby/shop time is limited due to wee ones lately so it would be handy if there was something simpler to use for gear model generation in this package.

Forgive me if this is a silly question but I figure if I can get nudged in the right direction I can continue on from there. Thanks!

As I have just gotten my first 3D printer, and wish to use it to fiddle with making gears in the not to distant future, I figured to try modeling a gear in FreeCAD but darned if I wasn't having trouble figuring out where that function is found. I know how to make various gears in Fusion as there are scripts readily available with dialog boxes to input parameters but all I've found so far on the FreeCAD forums is some Python code snippets. I have never learned how to program using Python, and while I'm always up for learning new stuff my hobby/shop time is limited due to wee ones lately so it would be handy if there was something simpler to use for gear model generation in this package.

Forgive me if this is a silly question but I figure if I can get nudged in the right direction I can continue on from there. Thanks!