Matt-Aburg

Ultra Member

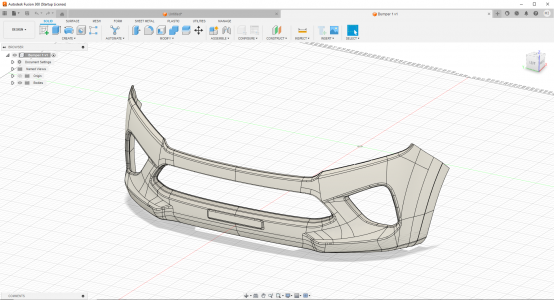

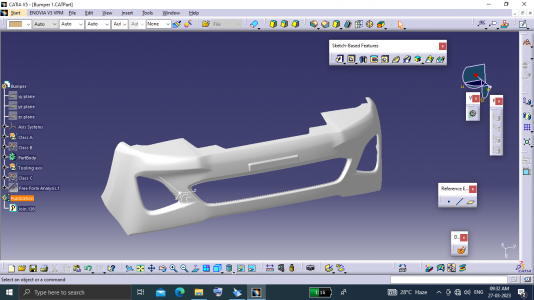

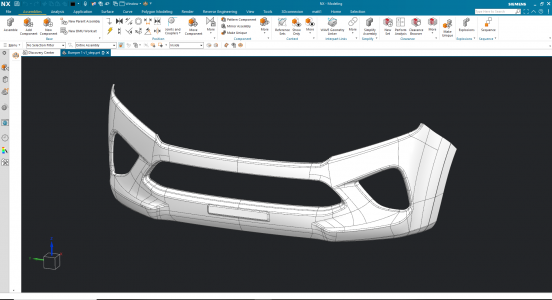

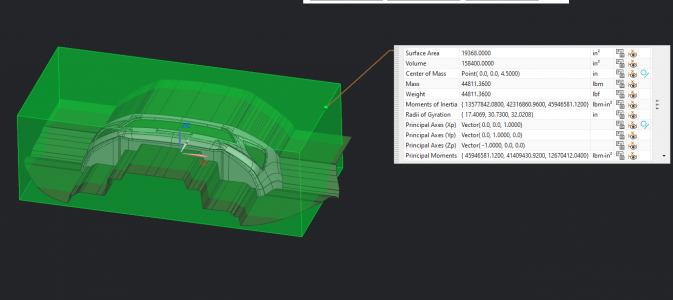

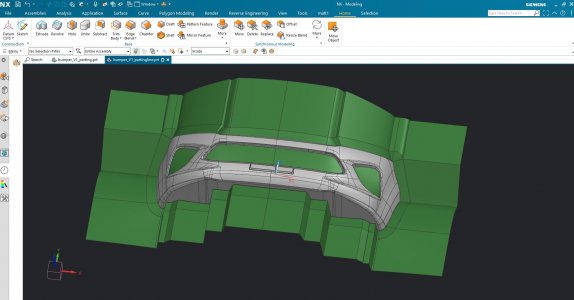

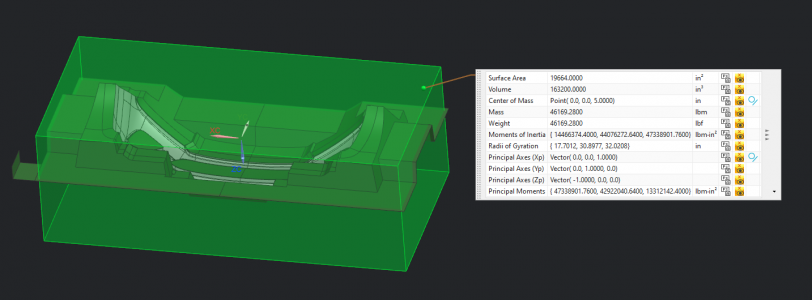

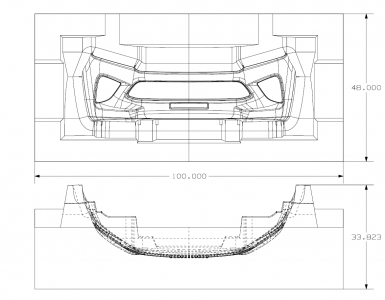

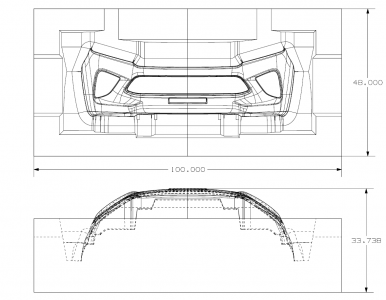

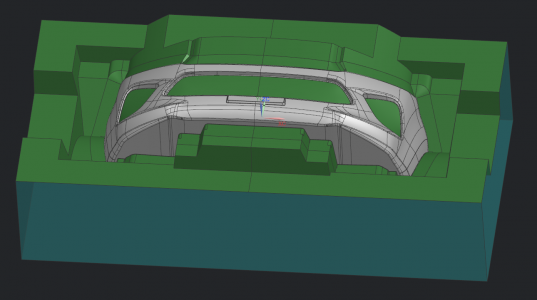

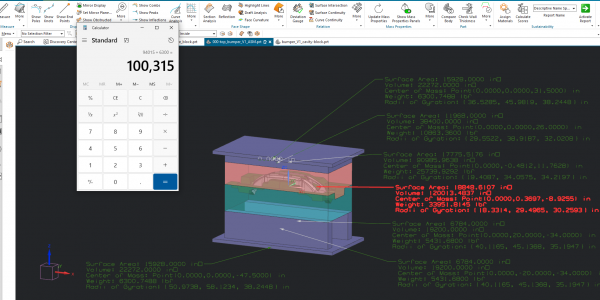

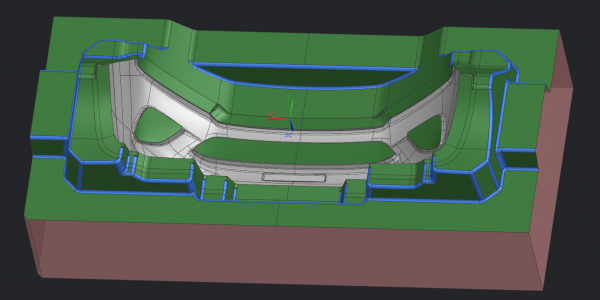

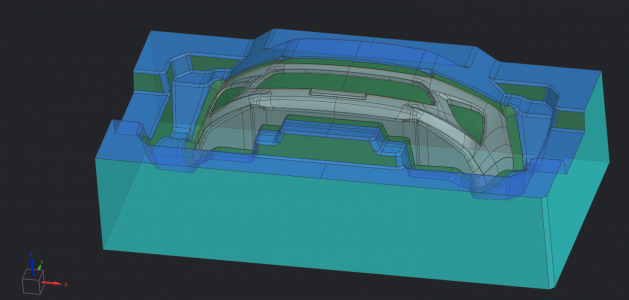

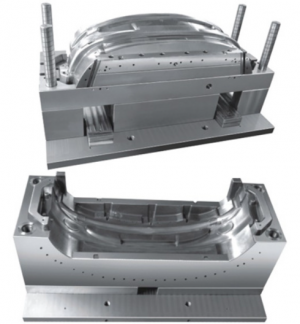

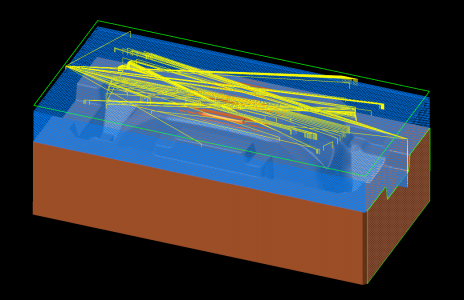

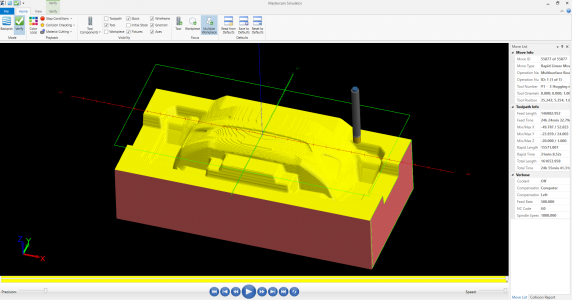

I was looking for a little challenge today. I want to Grabcad to find a plastic part to work with to keep up with mold design-surfacing skills. I came across this facia that is drawn in Catia (linked below). I then tried to import it into my paid software packages. Well of course, both Mastercam and Siemens want more money for that module. WTH, I though well lets see if it is possible in Fusion 360. Long story short... here is the screenshot.. Also proof with it into NX

So my evaluation so far of whether I will pay Autodesk is YES, because of..

1/ translators

2/ 3D machining capabilities, and umpteen million posts

3/ fastener library

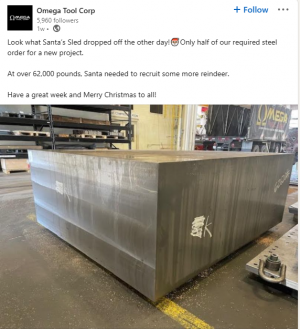

Merry Christmas!! a free part translator.. (well, 150 for 3 years almost free)...

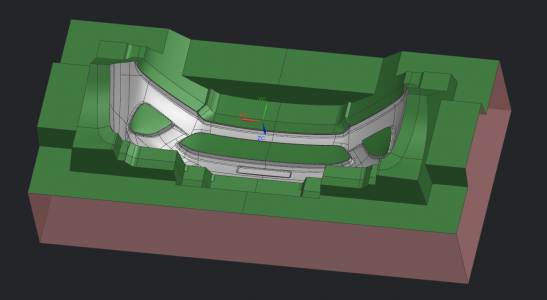

Next, now a partingline shall become.... Thanks to Autodesk, GrabCad, and the part designer (Nishanth kumar)

grabcad.com

grabcad.com

So my evaluation so far of whether I will pay Autodesk is YES, because of..

1/ translators

2/ 3D machining capabilities, and umpteen million posts

3/ fastener library

Merry Christmas!! a free part translator.. (well, 150 for 3 years almost free)...

Next, now a partingline shall become.... Thanks to Autodesk, GrabCad, and the part designer (Nishanth kumar)

Free CAD Designs, Files & 3D Models | The GrabCAD Community Library

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!

Attachments

Last edited: