Dabbler

ersatz engineer

I know of at least 3 C0636 (or equivalent) lathe owners in the group (now) only 2 in Calgary.

Janger and I were discussing several ideas and mods to the lathe, and I was wondering who all has this lathe?

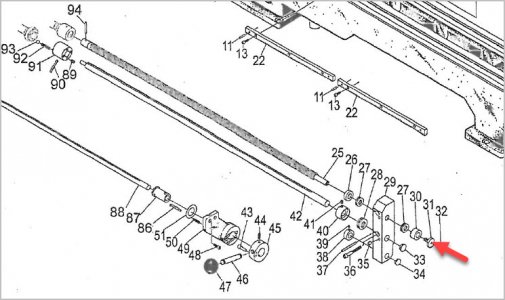

One thing in particular, is how much torque does it take to do an ELS on one of these lathes. I am looking at ways to measure real-time cutting torque using the lead screw -- and checking several lathes out to get more than one data point.

I happen to be rewiring my lathe right now (the prev owner removed the electric break and changed the wiring considerably). So there's that as well.

If you feel sheepish about announcing it publicly, then PM me and we can talk...

-- it wouldn't hurt to have our own support group, of a kind...

Janger and I were discussing several ideas and mods to the lathe, and I was wondering who all has this lathe?

One thing in particular, is how much torque does it take to do an ELS on one of these lathes. I am looking at ways to measure real-time cutting torque using the lead screw -- and checking several lathes out to get more than one data point.

I happen to be rewiring my lathe right now (the prev owner removed the electric break and changed the wiring considerably). So there's that as well.

If you feel sheepish about announcing it publicly, then PM me and we can talk...

-- it wouldn't hurt to have our own support group, of a kind...