Just a simple projecting showing how handy 3D printing can be. I bet lots of guys are thinking "what would I ever use one for" whereas after having one its like what a pain it would be not having one.

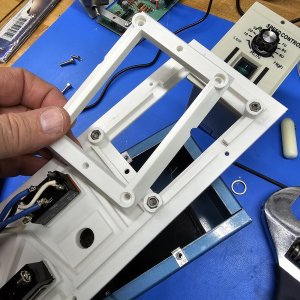

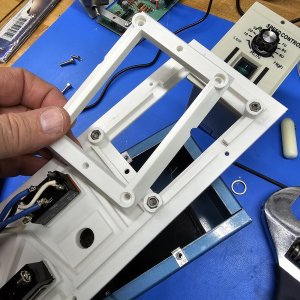

I had a cheapo amazon DC controller and wanted to recycle an enclosure I had

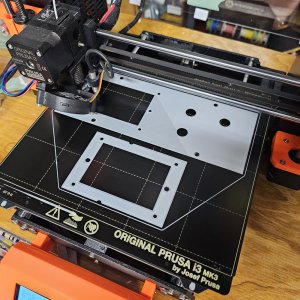

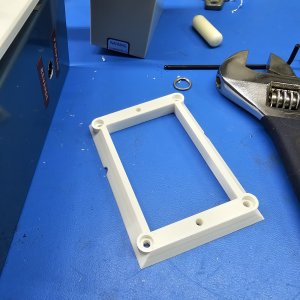

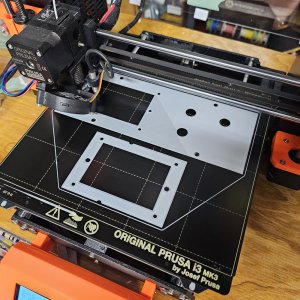

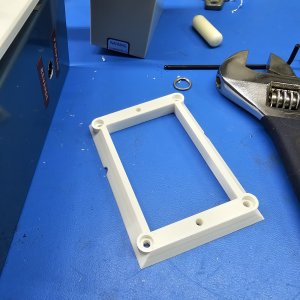

I printed it in two pieces that were then bolted together. This is only because ideally you want to print stuff with a complete flat side down and all feature facing upward. As this had features of both sides, its a way to accomplish that

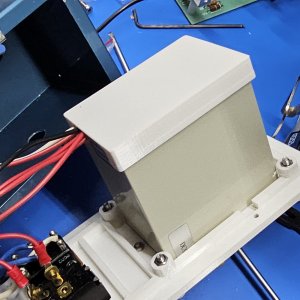

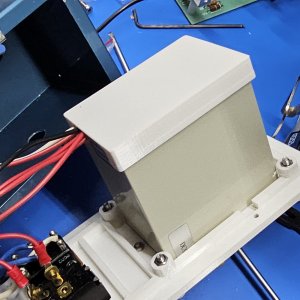

I also printed a little cover plate on the back so no wires could make contact with the case. Its a light press fit on but once install in the box is captive.

Why three switches? One switches the polarity for reverse, the other is start stop so I'm not using the cheap unit switch and also facilitates the larger toggle extension and the third is power on/off to the controller (never leave these cheapo electronics plugged in, some are a real hazard inside and I have not seen one that is CSA approved)

I had a cheapo amazon DC controller and wanted to recycle an enclosure I had

I printed it in two pieces that were then bolted together. This is only because ideally you want to print stuff with a complete flat side down and all feature facing upward. As this had features of both sides, its a way to accomplish that

I also printed a little cover plate on the back so no wires could make contact with the case. Its a light press fit on but once install in the box is captive.

Why three switches? One switches the polarity for reverse, the other is start stop so I'm not using the cheap unit switch and also facilitates the larger toggle extension and the third is power on/off to the controller (never leave these cheapo electronics plugged in, some are a real hazard inside and I have not seen one that is CSA approved)