Tmate

Well-Known Member

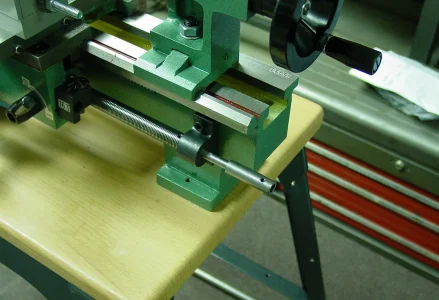

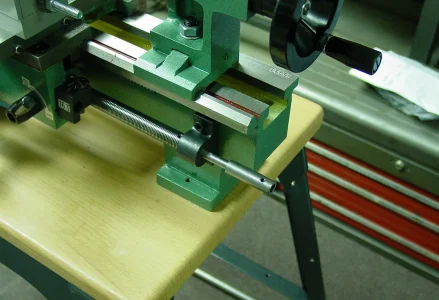

A good while back I bought a Grizzly mini lathe, and like my old Atlas 6 incher, I had to switch the gears to adjust the feed rate. My solution for that is pictured below.

I center drilled the lead screw with a 5/16" drill, then drilled and tapped a setscrew hole an inch or so from its end. I then made a female to male adaptor that slid into the end of the lead screw and fit on the shaft of a 50 rpm Grainger gearmotor. The male end of the adaptor had a flat milled into it. A drilled detent would have accomplished the same thing. I drilled and tapped a couple of holes in the end of the lathe and made a motor mounting bracket that bolted in place.

A DC model railroad transformer controlled the feed rate in forward and reverse.

I center drilled the lead screw with a 5/16" drill, then drilled and tapped a setscrew hole an inch or so from its end. I then made a female to male adaptor that slid into the end of the lead screw and fit on the shaft of a 50 rpm Grainger gearmotor. The male end of the adaptor had a flat milled into it. A drilled detent would have accomplished the same thing. I drilled and tapped a couple of holes in the end of the lathe and made a motor mounting bracket that bolted in place.

A DC model railroad transformer controlled the feed rate in forward and reverse.