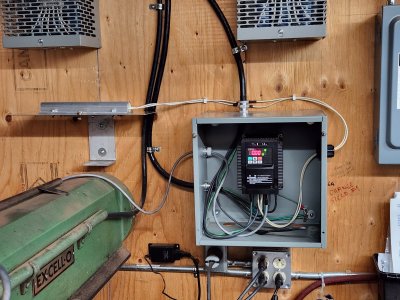

I finally decided to put a braking resistor onto the Hitachi WJ200 VFD for my Ex-Cell-O 602 milling machine which has a 2hp motor.

Previously I had a 3s acceleration phase, and a 3s deceleration phase. Trying to stop any faster than about 2.5s and it would trip and coast to a stop. The 3s was never a problem except when power tapping, which can be daunting at times.

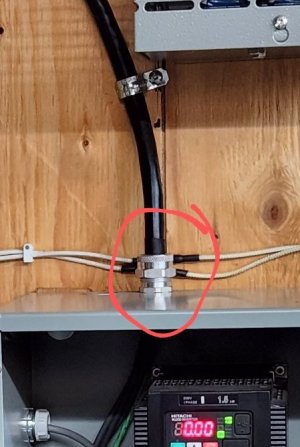

So I ordered a 50ohm 500w power resistor and hooked it up. Now I set it for 1s, and doesn't trip. I'm sure I can stop faster, which I will determine later, but 1s is quick enough for now.

I was going to buy a heat sink to set the brake on, but it was too expensive, so I just put the brake on a piece of 16g. aluminium sheet. Only time will tell if I need a heat sink, or maybe use of a small fan.

Next is to order one for my lathe.

Previously I had a 3s acceleration phase, and a 3s deceleration phase. Trying to stop any faster than about 2.5s and it would trip and coast to a stop. The 3s was never a problem except when power tapping, which can be daunting at times.

So I ordered a 50ohm 500w power resistor and hooked it up. Now I set it for 1s, and doesn't trip. I'm sure I can stop faster, which I will determine later, but 1s is quick enough for now.

I was going to buy a heat sink to set the brake on, but it was too expensive, so I just put the brake on a piece of 16g. aluminium sheet. Only time will tell if I need a heat sink, or maybe use of a small fan.

Next is to order one for my lathe.