I bought a 15pc set of premium 'roasted yellow' M35 cobalt drills off Ali that was a throw-in, on sale with another item. It finally made it through the bunged up CP strike plumbing. (Now just watch, they will manage to lose my $100 item, but I digress). Turns out they are actually decent. But they came in a thin plastic bag. Not false advertising, I just failed to realize - no drill case.

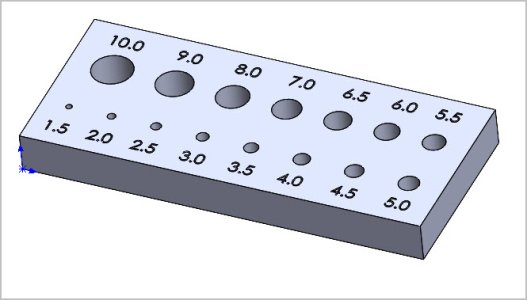

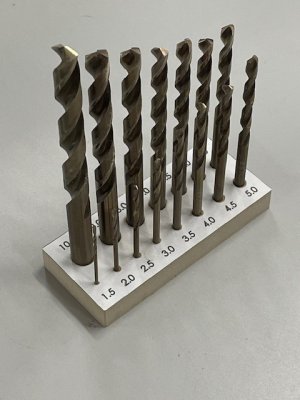

I'm not going to throw more money at it for a case so I drew up a sketch to use my standard method of drilling a block of wood which has served me well over the years. There is actually some layout considerations for spacing progressive increment sized objects but that's another subject. The issue is the paper I leave stuck on the wood to a) guide my hole-making and b) remain on for drill size ID ends up curling or degrading over time. Just wondering, I could call in a 3DP favor but I'd have to tweak the design a bit. I would increase the hole size just a bit for clearance. Increase the block depth a bit, make a drill 'bottom' vs through hole, maybe even shell it to save materials. But before I go down that path I'm just wondering, the drill size numbers are extrude-cut into the surface 1mm (I could make it anything). Would this relief show up visibly enough, or is that where those higher end multi-color printers are required? I probably could have had this thing made in the amount of time I typed. But if anyone wants an STL for their metric drills rolling around in a drawer let me know.

I'm not going to throw more money at it for a case so I drew up a sketch to use my standard method of drilling a block of wood which has served me well over the years. There is actually some layout considerations for spacing progressive increment sized objects but that's another subject. The issue is the paper I leave stuck on the wood to a) guide my hole-making and b) remain on for drill size ID ends up curling or degrading over time. Just wondering, I could call in a 3DP favor but I'd have to tweak the design a bit. I would increase the hole size just a bit for clearance. Increase the block depth a bit, make a drill 'bottom' vs through hole, maybe even shell it to save materials. But before I go down that path I'm just wondering, the drill size numbers are extrude-cut into the surface 1mm (I could make it anything). Would this relief show up visibly enough, or is that where those higher end multi-color printers are required? I probably could have had this thing made in the amount of time I typed. But if anyone wants an STL for their metric drills rolling around in a drawer let me know.