I recently purchased an Accusize D1-5 backing plate to install on a new 6" 4-jaw chuck, which I haven't bought yet.

This backing plate is 1.820" thick, not including the 1/8" flange.

Checking online for other manufacturers dimensions for comparison:

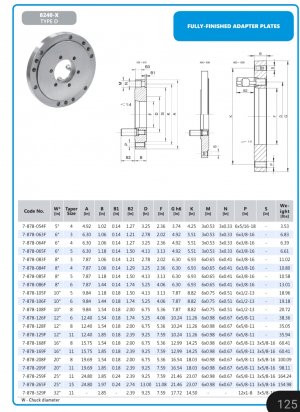

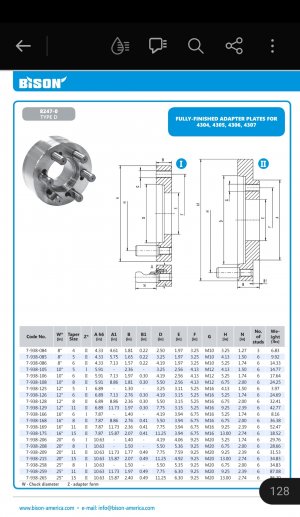

Bison: 1.350"

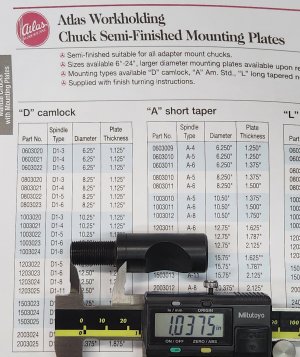

Atlas: 1.125"

Is there any reason I need to keep it so thick? Should I use it as is, or face it down to Atlas or Bison dimensions?

Maybe the Accusize plate was designed for Set-Thru style chucks?

This backing plate is 1.820" thick, not including the 1/8" flange.

Checking online for other manufacturers dimensions for comparison:

Bison: 1.350"

Atlas: 1.125"

Is there any reason I need to keep it so thick? Should I use it as is, or face it down to Atlas or Bison dimensions?

Maybe the Accusize plate was designed for Set-Thru style chucks?