terry_g

Ultra Member

I picked up a couple insert type threading bars a left and a right. They are decent quality for the price.

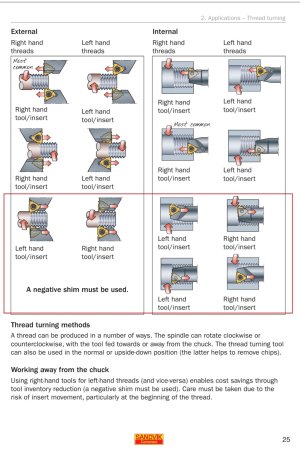

Rather than thread toward a shoulder I usually thread with the lathe in reverse and the tool bit upside down.

With the treading bar I was able to cut threads with the cutter on the back side of the stock right side up.

I like to watch the chips coming off as the threads cut.

This was practice cutting 5/8" 18 threads on a piece of mystery metal. I fed the bit in straight next time I will

try cutting with the compound set to 29 degrees.

Rather than thread toward a shoulder I usually thread with the lathe in reverse and the tool bit upside down.

With the treading bar I was able to cut threads with the cutter on the back side of the stock right side up.

I like to watch the chips coming off as the threads cut.

This was practice cutting 5/8" 18 threads on a piece of mystery metal. I fed the bit in straight next time I will

try cutting with the compound set to 29 degrees.