LatheInTheGame

New Member

Hi and thanks to all in avance

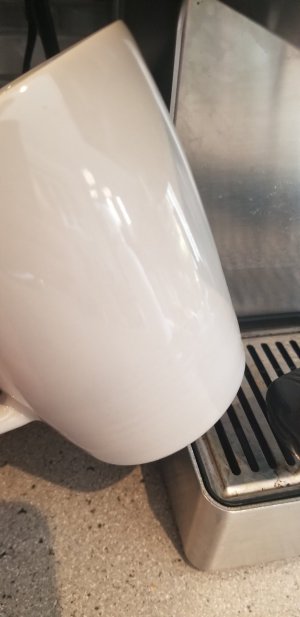

I'm in for a little project my wife asked me to do, modify our stainless Seaco expresso machine so her cup easily gets under the hahdle.

I know cutting stainless can be a hard task, if it still need to "look good".

Would appreciate any tips on this

I'm in for a little project my wife asked me to do, modify our stainless Seaco expresso machine so her cup easily gets under the hahdle.

I know cutting stainless can be a hard task, if it still need to "look good".

Would appreciate any tips on this