You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tips/Techniques Copying parts in a manual lathe

- Thread starter DavidR8

- Start date

Tips/Techniques

I like it David. Very cool. I actually watched enough to get the gist of it. But not the whole thing.

Need to figure out how to attach a Stylus like that so that it's on center.

I've always been pretty good at coordinating carriage and cross slide so it might even be easy for me. I think the hardest part is dealing with backlash. He appeared to be cutting while cranking the cross-slide both ways. I would have thought you only cut while pressing inward. But maybe that was just my impression.

Need to figure out how to attach a Stylus like that so that it's on center.

I've always been pretty good at coordinating carriage and cross slide so it might even be easy for me. I think the hardest part is dealing with backlash. He appeared to be cutting while cranking the cross-slide both ways. I would have thought you only cut while pressing inward. But maybe that was just my impression.

Maybe because he already had the 3D doo-dad beforehand so it warranted mounting in the TS. But the stylus setup looks awkward to my eye. Now it also has to be vertically on center & the TS is no longer available for any longer part to copy. Maybe just a short part run trick for a few artistic shapes, which is totally fine. They look nice. Another approach is a 2D template located to the rear of the lathe & stylus mounted to cross slide. Industrial versions even had hydraulic feed.

It is important that the stylus & cutting tool match exactly for the entire range of cutting profile. Maybe my eyes are playing tricks but in the video it almost looks like his hockey stick stylus might give a false contact read if the angle shank contacts before the cutting tool tangent.

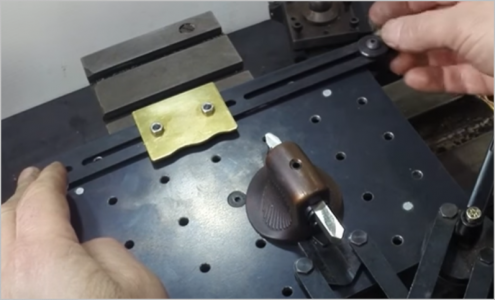

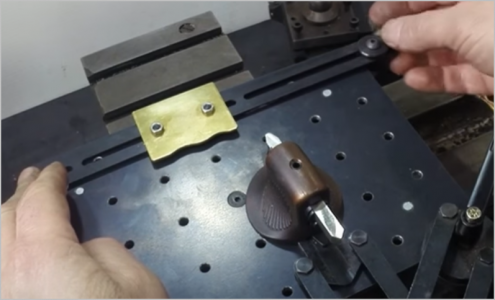

There was another gadget, I think Blondi was plugging it at some point. Kind of a hand held affair that slid on a platen on the cross slide? It appeared to work with very light cuts on brass but I value my 10 full length fingers LOL.

It is important that the stylus & cutting tool match exactly for the entire range of cutting profile. Maybe my eyes are playing tricks but in the video it almost looks like his hockey stick stylus might give a false contact read if the angle shank contacts before the cutting tool tangent.

There was another gadget, I think Blondi was plugging it at some point. Kind of a hand held affair that slid on a platen on the cross slide? It appeared to work with very light cuts on brass but I value my 10 full length fingers LOL.

Attachments

I think it was setup sold by Eccentric Engeneering call a turnado.There was another gadget, I think Blondi was plugging it at some point. Kind of a hand held affair that slid on a platen on the cross slide? It appeared to work with very light cuts on brass but I value my 10 full length fingers LOL.

I had a friend who was so good at turning shapes freehand, he laugh at me when I told him I built radius turning tool. He said balls , sphere are the easiest to turn. contoured lathe handles just takes practice. Last time I tried a ball it turned out reasonable for a first and I didn't need to pull out the radius turning tool out.

That’s made by Eccentric Engineering in Australia.Yup, that's the one. I don't recall seeing the (actual inventor) video but somehow doesn't look as scary anymore. Of note, here is his 2D copying attachment

View attachment 40998

This thread is giving me a few ideas. I have a project that I will need to copy a couple curved parts.

I will need to make three of the spoke covers and one of the handles. (Red Arrow)

The handle should be easy. The spoke cover a little harder. After the shape is made, I will need to cut them in half. (I hope it is half the diameter.) The issue is I will need to mill a small recess for what looks like a threaded disk(green circle), that I assume is glued into the recess. How I'm going to hold this after it is cut in half will be the hard part.

So far, all I have come up with is to leave a bit of stock attached to the spoke cover. Mill one half of the profile away over the spoke contour. The extra stock is what I could use to hold the cover while milling the recess. Sounds like it will work. Haha, talking myself thru this.

Looking at this photo, I realized the threaded hole in those disks appears to be off center. Ideas? Is that so you can line the cover up to the support underneath?

I will need to make three of the spoke covers and one of the handles. (Red Arrow)

The handle should be easy. The spoke cover a little harder. After the shape is made, I will need to cut them in half. (I hope it is half the diameter.) The issue is I will need to mill a small recess for what looks like a threaded disk(green circle), that I assume is glued into the recess. How I'm going to hold this after it is cut in half will be the hard part.

So far, all I have come up with is to leave a bit of stock attached to the spoke cover. Mill one half of the profile away over the spoke contour. The extra stock is what I could use to hold the cover while milling the recess. Sounds like it will work. Haha, talking myself thru this.

Looking at this photo, I realized the threaded hole in those disks appears to be off center. Ideas? Is that so you can line the cover up to the support underneath?