Was doing some maintenance on my coveralls (patching holes) when the sewing machine stitch selector failed. This is a 1994 vintage machine, made in Taiwan. And yes, I have to repair it because it is the boss’s machine… (or buy her a new one).

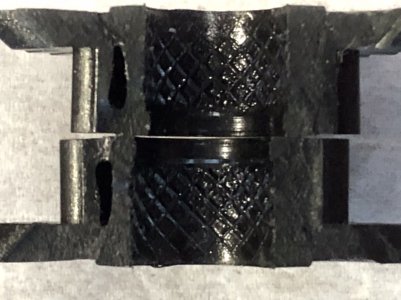

After disassembly of the sewing machine, I found this:

It is actually three pieces - two injection moulded plastic gear halves and the steel hub.

A view from the obverse and a side view.

This compound gear (spur gear together with a bevel gear) was injection moulded as a unit and then pressed onto the steel hub. The hub has knurl marks for better grip. The reason the gear failed was because of a manufacturing defect. You can clearly see the voids on the left hand side of the two halves.

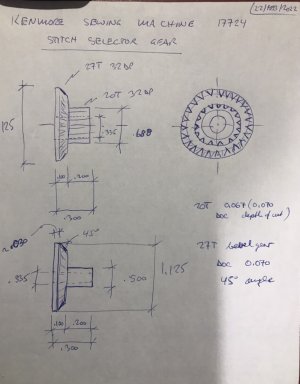

Some measuring and calculating revealed that they are 32 DP gears. I happen to have 6 of the set of 8 32 DP involute cutters (two are missing; one of them being the 26T to 34T one).

I am going to make the gear from two parts: a 20T spur gear pressed onto the hub extension of the 27T bevel gear (this is the cutter that is missing - I’ll use the 25T cutter I have and call it good). The whole thing will then be pressed & locktighted onto the OE steel hub. Going to use aluminum for the material. I will have to make some arbours to hold the individual parts for machining.

Pictures to come once I get to making the gear(s)…

After disassembly of the sewing machine, I found this:

It is actually three pieces - two injection moulded plastic gear halves and the steel hub.

A view from the obverse and a side view.

This compound gear (spur gear together with a bevel gear) was injection moulded as a unit and then pressed onto the steel hub. The hub has knurl marks for better grip. The reason the gear failed was because of a manufacturing defect. You can clearly see the voids on the left hand side of the two halves.

Some measuring and calculating revealed that they are 32 DP gears. I happen to have 6 of the set of 8 32 DP involute cutters (two are missing; one of them being the 26T to 34T one).

I am going to make the gear from two parts: a 20T spur gear pressed onto the hub extension of the 27T bevel gear (this is the cutter that is missing - I’ll use the 25T cutter I have and call it good). The whole thing will then be pressed & locktighted onto the OE steel hub. Going to use aluminum for the material. I will have to make some arbours to hold the individual parts for machining.

Pictures to come once I get to making the gear(s)…