Chicken lights

Forum Pony Express Driver

We are not off to a good start. The forum says my pictures are too large to upload... yet I've posted tons of photos before....

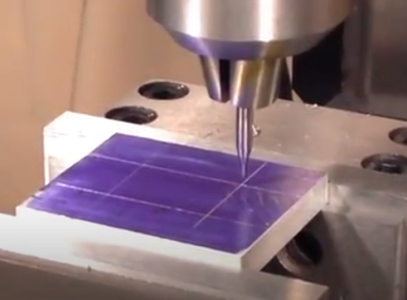

Microlux mini mill. Will try to download the PDF owners manual tomorrow.

Cannot use the (quill?) hand wheel to lower the cutting head, there is a large silver knob located at the face of the head that allows 25-50 thou of fine adjustment, moving the hand wheel at the same time.

DRO's shouldn't or power feeds "shouldn't" affect manual controls....?

The fault light lit up on the power feed when trying to use it, but I believe power feed is L to R, not up and down....?

Microlux mini mill. Will try to download the PDF owners manual tomorrow.

Cannot use the (quill?) hand wheel to lower the cutting head, there is a large silver knob located at the face of the head that allows 25-50 thou of fine adjustment, moving the hand wheel at the same time.

DRO's shouldn't or power feeds "shouldn't" affect manual controls....?

The fault light lit up on the power feed when trying to use it, but I believe power feed is L to R, not up and down....?

Last edited: