slow-poke

Ultra Member

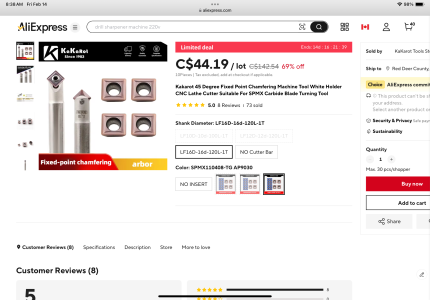

Looking for Ali Express type suggestions for a carbide insert tool holder and inserts for chamfering the open end after facing when using a lathe

I have been using SDNCN1212H07, however would prefer something with a smaller angle and ideally a holder that projects to the left.

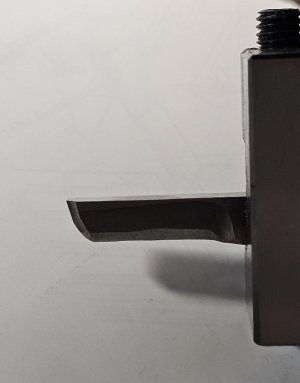

Something like the blue one in the image below.

I have been using SDNCN1212H07, however would prefer something with a smaller angle and ideally a holder that projects to the left.

Something like the blue one in the image below.

Last edited: