Brent H

Ultra Member

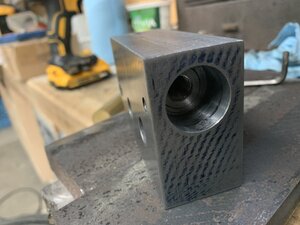

So this one is needed so I can support the mandrels better when making gears. I have some cutting to do on a longer shaft so this project is a must.

This is a small one for a 4” rotary table:

I you could just add some water and it would expand - that would be sweet! But no .....

The parts are coming from a heavy piece of angle I torched up and the centre holder part is from a piece of the hull (bow section) of the ship I work on. We installed a new bow thruster in 2016 so this chunk has been in the “future plans” section for a while - LOL. It is Grade E steel which means it is supposed to retain its properties down to -40° C. Ice breaking -LOL

Here is the pile of other steel:

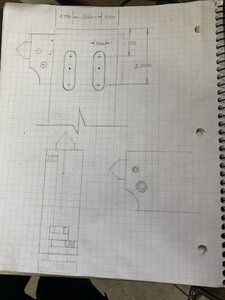

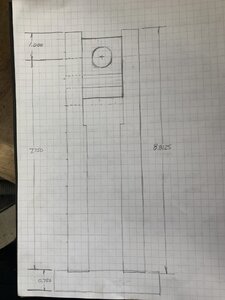

Here are the very rough plans - still jigging them a bit:

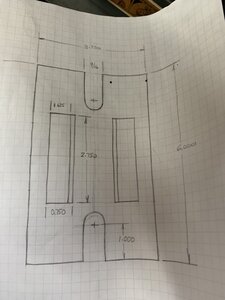

And the base:

I got a good start on it today - will post more after I make the dinner ......

This is a small one for a 4” rotary table:

I you could just add some water and it would expand - that would be sweet! But no .....

The parts are coming from a heavy piece of angle I torched up and the centre holder part is from a piece of the hull (bow section) of the ship I work on. We installed a new bow thruster in 2016 so this chunk has been in the “future plans” section for a while - LOL. It is Grade E steel which means it is supposed to retain its properties down to -40° C. Ice breaking -LOL

Here is the pile of other steel:

Here are the very rough plans - still jigging them a bit:

And the base:

I got a good start on it today - will post more after I make the dinner ......