Hello all,

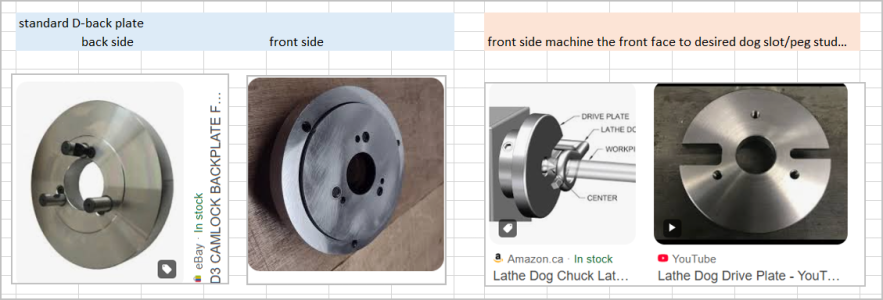

I have a couple of jobs coming up that require me to turn between centres. Previously I had just chucked up a piece of stock in the 3 jaw and drove the dog off one of the jaws. This works ok but I would like to refrain from running the dog against the jaws. My Bantam requires a somewhat hard to find MT 4/12 sleeve or centre to fit the spindle nose. I’m thinking about making a drive plate with an integer all MT bore to take the centre. Is there any reason I shouldn’t try this? I can’t find any commercially made versions, so I wonder if it’s not a practical idea. Any input is welcome.

Thanks.

I have a couple of jobs coming up that require me to turn between centres. Previously I had just chucked up a piece of stock in the 3 jaw and drove the dog off one of the jaws. This works ok but I would like to refrain from running the dog against the jaws. My Bantam requires a somewhat hard to find MT 4/12 sleeve or centre to fit the spindle nose. I’m thinking about making a drive plate with an integer all MT bore to take the centre. Is there any reason I shouldn’t try this? I can’t find any commercially made versions, so I wonder if it’s not a practical idea. Any input is welcome.

Thanks.