There is a cricket in my mill drive train. have a listen in the video. I've been told it's spindle bearings. Listening with stethoscope on the spindle holding casting it seems to sound off.

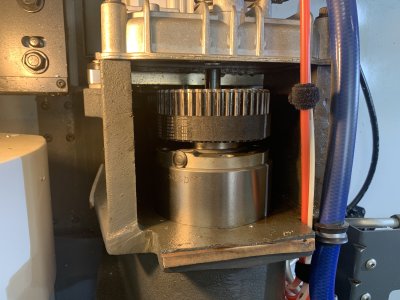

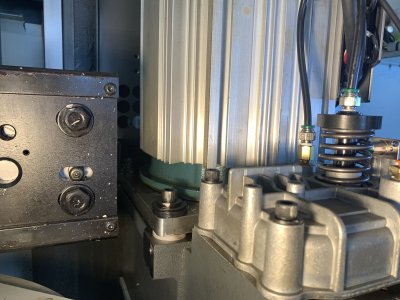

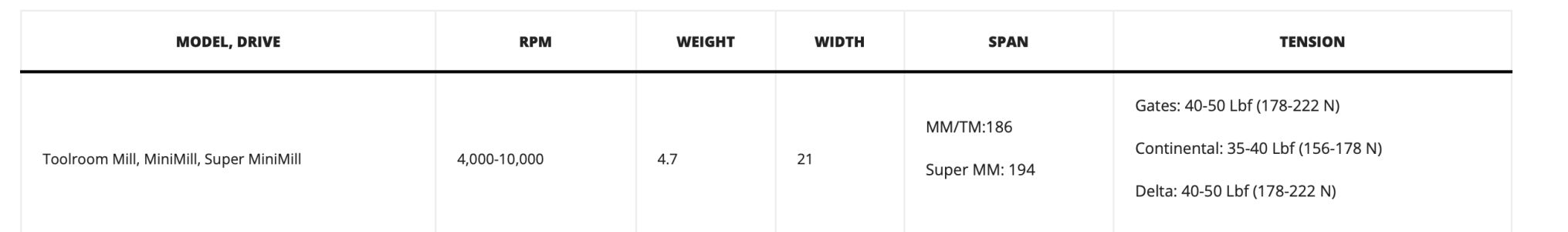

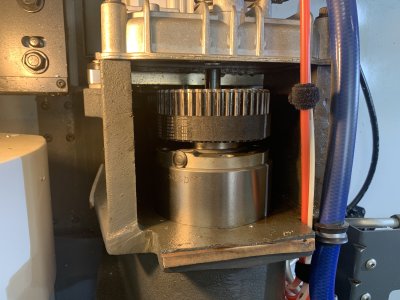

A few things we thought were odd. The belt is not very wide... the pulleys could have a belt twice as wide? why is that? and the belt is riding at the bottom of the pulley which is also odd. the belt is also a bit sticky. I could potentially replace the belt. perhaps with a wider one. I'll have to look in the maintenance manual and see if they list the belt size. What say you?

.mov video attached as zip and and pics.

A few things we thought were odd. The belt is not very wide... the pulleys could have a belt twice as wide? why is that? and the belt is riding at the bottom of the pulley which is also odd. the belt is also a bit sticky. I could potentially replace the belt. perhaps with a wider one. I'll have to look in the maintenance manual and see if they list the belt size. What say you?

.mov video attached as zip and and pics.