-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AXA Tool Holder for Tapered Cut Off Blades

- Thread starter YYCHM

- Start date

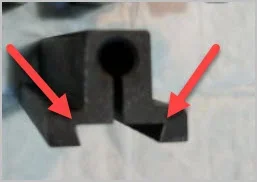

I have some 15mmcut off blades that look like this in profile....

View attachment 20985

Where can I get an AXA tool holder for these things?

Baring an AXA tool holder, any tool holder....

Thanks,

Craig

Common cut off blade tool holder is one with a 7 degree slope / angle at the nose and rear tightening screw that accommodates 1/2" blades. I'm not aware of any AXA cut off blade tool holder in the above configuration that will take a 15mm / 5/8" blade unless you can modify same.

Last edited:

Common cut off blade tool holder is one with a 7 degree slope / angle at the nose and rear tightening screw accommodate 1/2" blades. I'm not aware of any AXA cut off blade tool holder in the above configuration that will take a 15mm / 5/8" blade unless you modify same.

Ya, I'm beginning to conclude that. BXA takes 11/16 blades, but the holder won't fit an AXA tool post.

Ya, I'm beginning to conclude that. BXA takes 11/16 blades, but the holder won't fit an AXA tool post.

One really needs a super solid cut off blade holder to reduce cutter chatter and vibrations at the face, modifying an AXA tool holder might not provide you with that.

What is the thickness of your blades?

About 2.4mm.

About 2.4mm.

So it's 3/32". Another question was do you own a AXA cut off blade holder now, I may have just the ticket that should work.

So it's 3/32". Another question was do you own a AXA cut off blade holder now, I may have just the ticket that should work.

Ya, I have an AXA cut off blade holder that takes 1/2" P-Type blades which will apparently work if you shim the blade upright or mill a relief slot in holder. Would have reduce the blades to 1/2" somehow. Carbide endmill perhaps?

Hey Craig, here's just the ticket you need. Presently holds a 3/32x5/8x5 blade in a regular AXA holder with 1/2" slot.

It's yours should you want it, call it a treat on me.

View attachment 21000View attachment 21001View attachment 21002View attachment 21005

Where did you get that from? I've been searching and searching and not finding anything.

Hey Craig, do you want it? I got it shortly after getting my lathe only because the blade was given to me so then I needed a 5/8" holder. Haven't used this for years, back then I started out with a small box of round mystery stock and me without a metal saw. I learned to part with this set up although I have my go to AXA 1/2" cut off tool holder.

Nose of the blade has a finger nail grove ground providing a 7 degree cutting angle. Heal of the blade was rounded so I wouldn't slice my hand again.

Just say the word buddy and I'll package it up then pop it in the post Monday.

Nose of the blade has a finger nail grove ground providing a 7 degree cutting angle. Heal of the blade was rounded so I wouldn't slice my hand again.

Just say the word buddy and I'll package it up then pop it in the post Monday.

Hey Craig, do you want it? I got it shortly after getting my lathe only because the blade was given to me so then I needed a 5/8" holder. Haven't used this for years, back then I started out with a small box of round mystery stock and me without a metal saw. I learned to part with this set up although I have my go to AXA 1/2" cut off tool holder.

Just say the word and I'll package it up then pop it in the post Monday.

PM sent.

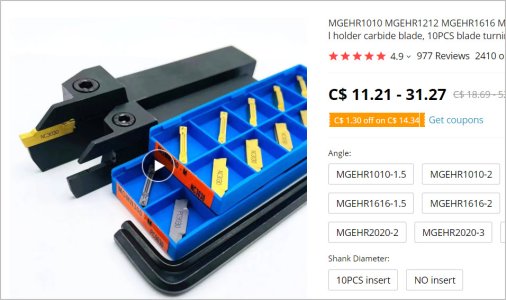

This is one of the (many) reasons I got frustrated with those blades. I suspect they were popular holders from another era but most of the modern tooling blocks seem to be orientated around rectangular section blades. I've seen some with an angle but on the bottom but the geometry didn't match and/or the blade height. If it cocks the blade at any angle, parting is a frustrating mess. So with rectangular notch the options are a HSS T-shape which works well. Or a carrier with a carbide insert. So my logic was if I'm going to go carbide cutter, may as well get a 5/8" toolholder & grip the shank it in the same block as any other tool. I have some cheapo's from Ali & never looked back.

This is one of the (many) reasons I got frustrated with those blades. I suspect they were popular holders from another era but most of the modern tooling blocks seem to be orientated around rectangular section blades. I've seen some with an angle but on the bottom but the geometry didn't match and/or the blade height. If it cocks the blade at any angle, parting is a frustrating mess. So with rectangular notch the options are a HSS T-shape which works well. Or a carrier with a carbide insert. So my logic was if I'm going to go carbide cutter, may as well get a 5/8" toolholder & grip the shank it in the same block as any other tool. I have some cheapo's from Ali & never looked back.

There is huge confusion out there regarding the P and T designations, no one seems to agree with what they actually mean. There's T shaped where the top and bottom are parallel, then there's tapered where the top and bottom are parallel, and then there is tapered where the top and bottom are not parallel. Very Very frustrating.

You can buy rigid, rectangular shanked holder + a 10-pack selection of inserts for the price of the dedicated, ill-fitting parting block. They are knock-offs of big boy holders but as mentioned I'm perfectly happy with mine. The inserts come in different flavors, I haven't found much difference in them but I keep my aluminum cutters separate from the steel just to confine the wear.

Attachments

darrin1200

Darrin

Is this on Amazon or eBay?You can buy rigid, rectangular shanked holder + a 10-pack selection of inserts for the price of the dedicated, ill-fitting parting block. They are knock-offs of big boy holders but as mentioned I'm perfectly happy with mine. The inserts come in different flavors, I haven't found much difference in them but I keep my aluminum cutters separate from the steel just to confine the wear.

I find Ali has a better selection of them for some reason (search 'parting tool')

www.aliexpress.com

www.aliexpress.com

Ebay has them too, sometimes the seller is one of the same. But they also seem to have a lot of weird stuff from India. Or blade within a clamp within a holder....

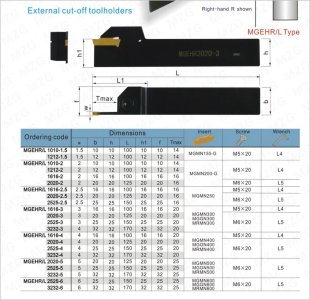

If you type in 'MGEHR' you will land closer &then can search stores, ideally tooling supply vs random merchandise supply

Suspect Bangood is the same as Ali. I don't use them much for no particular reason, I find its close enough to Ali

Accusize carries but I'd bet you a Tims is the exact same thing at higher price

accusizetools.com

accusizetools.com

Look for the vendors cross reference table because the terminology is not always the same but generically they come in shank thickness like 10,12,16,20 mm

Sometimes the holder + inserts are a good package deal, sometimes you will find stores with better selection of inserts only

www.aliexpress.com

www.aliexpress.com

parting tool - Buy parting tool with free shipping on AliExpress

Quality parting tool with free worldwide shipping on AliExpress

Ebay has them too, sometimes the seller is one of the same. But they also seem to have a lot of weird stuff from India. Or blade within a clamp within a holder....

If you type in 'MGEHR' you will land closer &then can search stores, ideally tooling supply vs random merchandise supply

Suspect Bangood is the same as Ali. I don't use them much for no particular reason, I find its close enough to Ali

Accusize carries but I'd bet you a Tims is the exact same thing at higher price

Indexable Cut-off Tool Holders with Carbide Inserts for Steel or Aluminum

Cut-Off Holder, Parting Tool with 10 Carbide Inserts Each set includes: 1 indexable cut-off holder 10 carbide inserts SKU Holder Size Tool Holder Insert Code Insert SKU Machining Materials 2387-0001INS 1/4" x 3/8'' MGEHR04-2 MGMN200 2403-4022 Steel 2387-0003INS 3/8'' x 3/8" MGEHR06-2J MGMN200...

Look for the vendors cross reference table because the terminology is not always the same but generically they come in shank thickness like 10,12,16,20 mm

Sometimes the holder + inserts are a good package deal, sometimes you will find stores with better selection of inserts only

21.74C$ 38% OFF|Mzg Mgehr Groove Width 2.0 3.0 4.0 Mm Cnc Lathe Machining Cutting Mgmn Mrmn Toolholders Cutter Parting Face Grooving Tools - Turning Tool - AliExpress

Smarter Shopping, Better Living! Aliexpress.com

Attachments

The carrier blocks that Dusty showed in principle should take care of using the HSS blades. But (at least the one I had way back when) had a few issues. They did not have good corner geometry, basically filleted as a function of the tool nose radius. That mean the cutting edge rests on that tiny point tangent. Not good for positioning or retention. It also didn't fit the HSS angles or blade depth, but that could be a function of so many different variations out in the wild. Maybe it fit their own. I also found it took a lot of unnecessary tool holder set screw gronk to overcome the bending tension. Looking at his the hole looks bigger than what I recall on mine so maybe they are evolving over time.

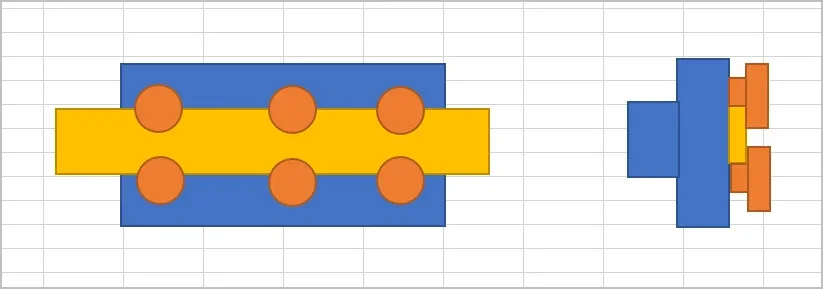

I made a rudimentary holder from scrap which worked surprisingly well. Hopefully sketch makes sense, if not ask. But I was using HSS parting blade for some one-off grooving dimensions, basically grinding the shape on the end of blade. It wouldn't be optimal for parting because of the infeed force acts to slide the blade along the block although I bet it better than my India Special. I have ground regular 1/4" HSS shanks for purposes like this but its just whole lot more material to take away whereas the parting blades are thinner & more deeper in vertical section.

I made a rudimentary holder from scrap which worked surprisingly well. Hopefully sketch makes sense, if not ask. But I was using HSS parting blade for some one-off grooving dimensions, basically grinding the shape on the end of blade. It wouldn't be optimal for parting because of the infeed force acts to slide the blade along the block although I bet it better than my India Special. I have ground regular 1/4" HSS shanks for purposes like this but its just whole lot more material to take away whereas the parting blades are thinner & more deeper in vertical section.

Attachments

Hey Craig, do you want it? I got it shortly after getting my lathe only because the blade was given to me so then I needed a 5/8" holder. Haven't used this for years, back then I started out with a small box of round mystery stock and me without a metal saw. I learned to part with this set up although I have my go to AXA 1/2" cut off tool holder.

Nose of the blade has a finger nail grove ground providing a 7 degree cutting angle. Heal of the blade was rounded so I wouldn't slice my hand again.

Just say the word buddy and I'll package it up then pop it in the post Monday.

Ahhhh Bill.... You sent me the AXA tool holder.....

Not just the blade holder.. I need to pay you for the AXA tool holder at the very least.....

Ahhhh Bill.... You sent me the AXA tool holder.....

View attachment 21124

Not just the blade holder.. I need to pay you for the AXA tool holder at the very least.....

Why? Let me know how it works out, enjoy my friend.