This can work, but maybe not the ideal method. Two things that stick out to me that might not be a problem right now as your program is small and simple, but could become an issue later as it grows. As I mentioned, not using interrupts you are waiting for your program to decide to ..........

Not sure if that makes sense, your code can work the way you have it today, but learning and structuring your code to use functions and interrupts will make it easier on you later if you want to add features or make changes.

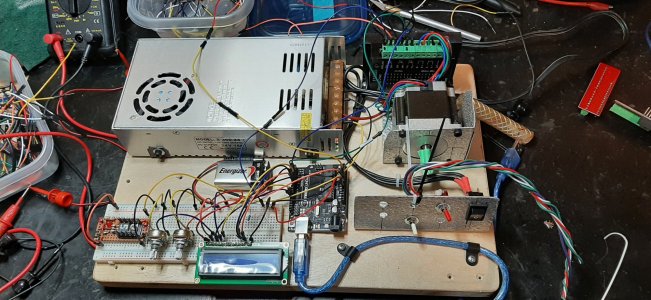

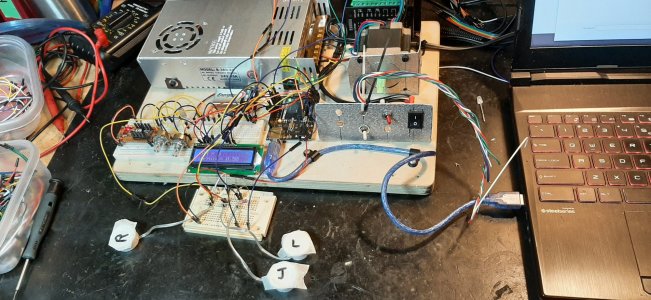

I had it working with the previous program, then took your advice and incorporated an interrupt for the limit switch, and only write to the LCD once per loop . I also took the display and stop functions out of the main loop. Good learning along the way, lots of time invested but lots of that learning time, but all good. Need more projects for the Arduino now.

Thanks for the input.

Below is the latest code if anyone is interested

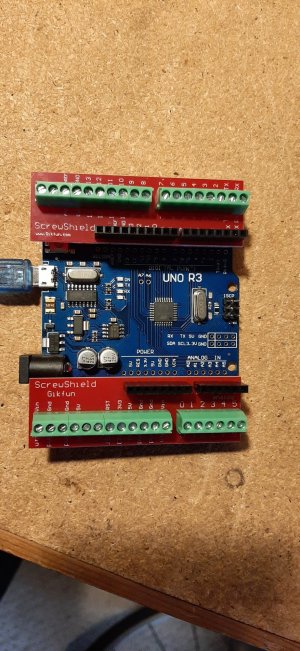

/*This program is intended for an Arduino UNO to run a power feed on a milling machine x axis. It drives a TB6600 Stepper motor controller

* running a NEMA23 stepper motor. It display feed rate, based on 0.100"/revolution of the lead screw.

* It accomodates a limit switch and displays the status of a limit violation.

* April 12 2022

* Enable signal to motor controller is LOW to enable motor

* variable "stopp" = 0 to enable motor

*

*/

#include <LiquidCrystal.h>

/*

LCD RS pin to digital pin 12

LCD Enable pin to digital pin 11

LCD D4 pin to digital pin 4

LCD D5 pin to digital pin 5

LCD D6 pin to digital pin 6

LCD D7 pin to digital pin 7

LCD R/W pin to ground

10K resistor:

ends to +5V and ground

wiper to LCD VO pin (pin 3 on display!)

6600 motor controller set to 400

*/

const int dirpinout = A5; //direction pin out to controller

const int dir_in = A2; //direction control pin in from switch

int dir; // sets table direction initially CW is table left

const int enablepin = 8; //enable pin out to controller

int enableout; //sets motor off to start

const int pulse = A4; // pulse out pin to controller

const int potin = A0; //speed pot connected to pin A0

int speedpulse; // pulse delay for speed management

const int runpin = A1; //run button enables or disables motor

int runn; //runn state(low to run)

const int jogin = A3; //jog switch in

int jogout; //jog out

const int limitpin = 2; //limit switch input

const int limitled = 13; // limit indicator connected to pin 13** may not be connected

int limit; //limit switch state

unsigned long tsrpm = 0; //tsrpm is start of timer for rpm

unsigned long tfrpm = 0; //tfrpm is stoptime for rpm count

int loops = 0; //loops is counter for loop cycles to use for rpm

int rpm = 0; //rpm

const int setpulse = 1600; //set to pulse setting on controller

volatile int stopped = 1; //stop is used to stop motor till a manual reset by activating jog

// initialize the library by associating any needed LCD interface pin

// with the arduino pin number it is connected to

const int rs = 12, en = 11, d4 = 4, d5 = 5, d6 = 6, d7 = 7;

LiquidCrystal lcd(rs, en, d4, d5, d6, d7);

void limitisr () {

stopped = 1; //stopped flag 1 should stop motor

//Serial.println("isr"); //used to troubleshoot

}

void setup() {

Serial.begin(9600); // send and receive at 9600 baud

pinMode(limitpin, INPUT_PULLUP); //limitswitch low when violated

pinMode (dir_in, INPUT_PULLUP); // switch takes pin low, otherwise, pin is high due to pullup, setting direction

pinMode(runpin, INPUT_PULLUP); //Run button enables motor to run

pinMode(jogin, INPUT_PULLUP); //Jog button in

pinMode (limitled, LED_BUILTIN); //just an indicator

pinMode (enablepin, OUTPUT); //high to controller to enable

pinMode (pulse, OUTPUT); //pulse to controller

pinMode(dirpinout, OUTPUT); //dir to controller for clockwise ****check this

lcd.begin(16, 2); // set up the LCD's number of columns and rows:

loops = 0; //sets completed loops to 0

attachInterrupt(digitalPinToInterrupt(limitpin), limitisr, LOW);

}

void loop() { //main loop

limit = digitalRead(limitpin);

runn = digitalRead(runpin); //zero to run, one to not run

jogout = digitalRead(jogin); //jogs motor if jog button pushed

//reset after limit violation

if ((limit == 1) && (jogout == LOW)) { //if limit ok and jog button pushed, reset stopp flag

stopped = 0;

}

if (stopped == 1) { //stopp == 1 disables motor

stopp(); //go to stopp function

}

else {

++loops; //increments counter for loops

}

if (loops == 1) { //gets time of first loop since a reset

tsrpm = millis(); //sets the time of the start tsrpm

}

else if (loops == setpulse) { //checks to see if the number of loops equals the number of steps on controller

tfrpm = millis(); //gets final time for rpm calculation

loops = 0; //resets loops counter

displaydata(); //goes to display data function

}

dir = digitalRead(dir_in); //reads motor direction according to switch

digitalWrite(dirpinout, dir); //sets dir pin to controller

if ((stopped == 0) && (runn == 0)) { // if run on and limit not reached, enable controller

digitalWrite(enablepin, LOW); //enables motor

}

else if ((stopped == 0) && (digitalRead(jogin) == 0)) { //if jog on and limit not reached, enable controller

digitalWrite(enablepin, LOW); //enbables motor

}

else {

digitalWrite(enablepin, HIGH); //disable controller see if this allows manual movement of table

}

speedpulse = analogRead (potin); //reads speed pot

speedpulse = map (speedpulse, 0, 1023, 10, 16000); //converts pot to speed delays max is 16383

digitalWrite (pulse, HIGH); //pulses motor

delayMicroseconds(100); //100 usec pulse delay

digitalWrite (pulse, LOW); //pulses motor off

delayMicroseconds(speedpulse); //delay

}

void displaydata() { //function to display data is called once per loop

rpm = 60000 / (tfrpm - tsrpm); //converting numbers to minute values

lcd.clear();

lcd.print("RPM Feed in/min");

lcd.setCursor(0, 1);

lcd.print(rpm);

lcd.print(" --- ");

lcd.print(rpm * 0.1);

}

void stopp() { //stopp function for limit violation

lcd.clear();

lcd.print("Clear limit then");

lcd.setCursor(0, 1);

lcd.print("Jog to reset");

delay (100);

}