Tom Kitta

Ultra Member

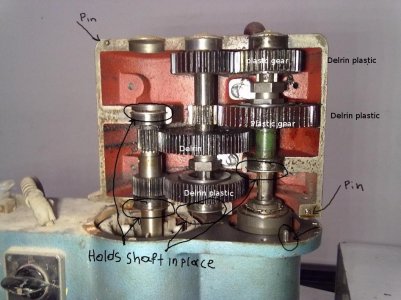

So this is like the first time for me where... I cannot remove the cover of a gear box. The front opens about the inch, or front and back for about 1/4 of an inch and that is it. Trying to lift it, pry off evenly etc. Playing with the gears inside etc. Nothing seems to work. I am afraid using craw bar to take the cover off may damage something.

All gears that I can see are helical and look like new. the reason for taking the cover off is rattling sound which seems to be due to the lower grease seal breaking off from one of the spindle bearings - not exactly a huge "issue" but a bit unpleasant.

I now have two Arboga drill presses - my other one is a bit taller, with smaller round drilling surface, speed range of 8 speeds but tops out at 1500 rpm vs. over 3000 for the G2508. Not sure yet which one I want to keep - but I first need to resolve the metal seal rattle.

Here are some images.

![IMG_20231203_202229[1].jpg IMG_20231203_202229[1].jpg](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 2000 957'%2F%3E)

![IMG_20231203_202242[1].jpg IMG_20231203_202242[1].jpg](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 957 2000'%2F%3E)

![IMG_20231203_202313[1].jpg IMG_20231203_202313[1].jpg](data:image/svg+xml;charset=utf-8,%3Csvg xmlns%3D'http%3A%2F%2Fwww.w3.org%2F2000%2Fsvg' viewBox%3D'0 0 957 2000'%2F%3E)

Any ideas? Mid image shows extent I can open. Or if I do it evenly its about 1/4" per side.

All gears that I can see are helical and look like new. the reason for taking the cover off is rattling sound which seems to be due to the lower grease seal breaking off from one of the spindle bearings - not exactly a huge "issue" but a bit unpleasant.

I now have two Arboga drill presses - my other one is a bit taller, with smaller round drilling surface, speed range of 8 speeds but tops out at 1500 rpm vs. over 3000 for the G2508. Not sure yet which one I want to keep - but I first need to resolve the metal seal rattle.

Here are some images.

![IMG_20231203_202229[1].jpg IMG_20231203_202229[1].jpg](/data/attachments/48/48984-38861ab60e7b0de8620b9010654316f5.jpg)

![IMG_20231203_202242[1].jpg IMG_20231203_202242[1].jpg](/data/attachments/48/48985-43195ddcd4b6a7766080c1e702f358c9.jpg)

![IMG_20231203_202313[1].jpg IMG_20231203_202313[1].jpg](/data/attachments/48/48986-385618b3167d5bae5edb913866a5f43b.jpg)

Any ideas? Mid image shows extent I can open. Or if I do it evenly its about 1/4" per side.