deleted_user

Super User

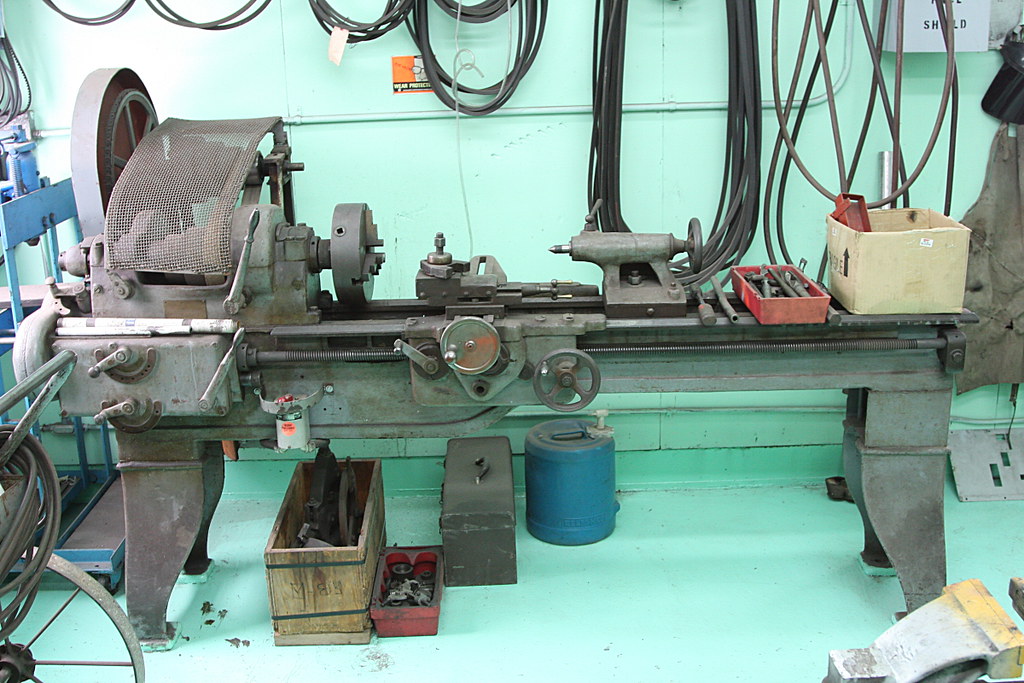

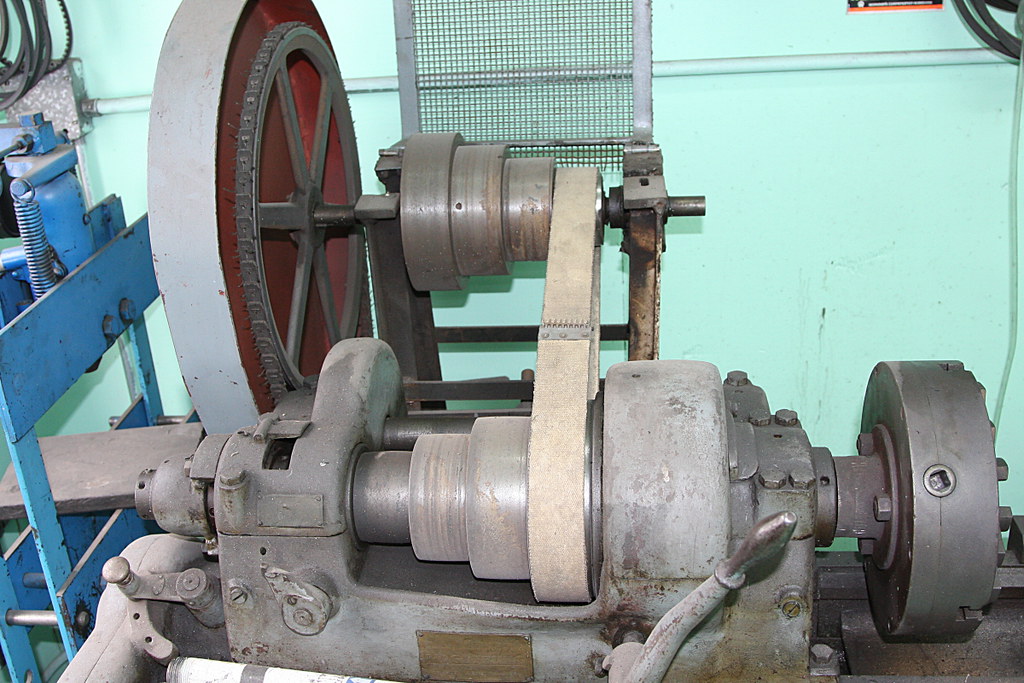

There is a John Bertram Lathe for sale on Kijiji for $2000. I'd suspect you can pick it up a little less because this wont be an easy mover.

If I had my retirement home and shop I'd not be telling everyone this, I'd be up in Peterborough loading this up on a truck.

www.kijiji.ca

www.kijiji.ca

If I had my retirement home and shop I'd not be telling everyone this, I'd be up in Peterborough loading this up on a truck.

Kijiji - Buy, Sell & Save with Canada's #1 Local Classifieds

Visit Kijiji Classifieds to buy, sell, or trade almost anything! New and used items, cars, real estate, jobs, services, vacation rentals and more virtually anywhere.

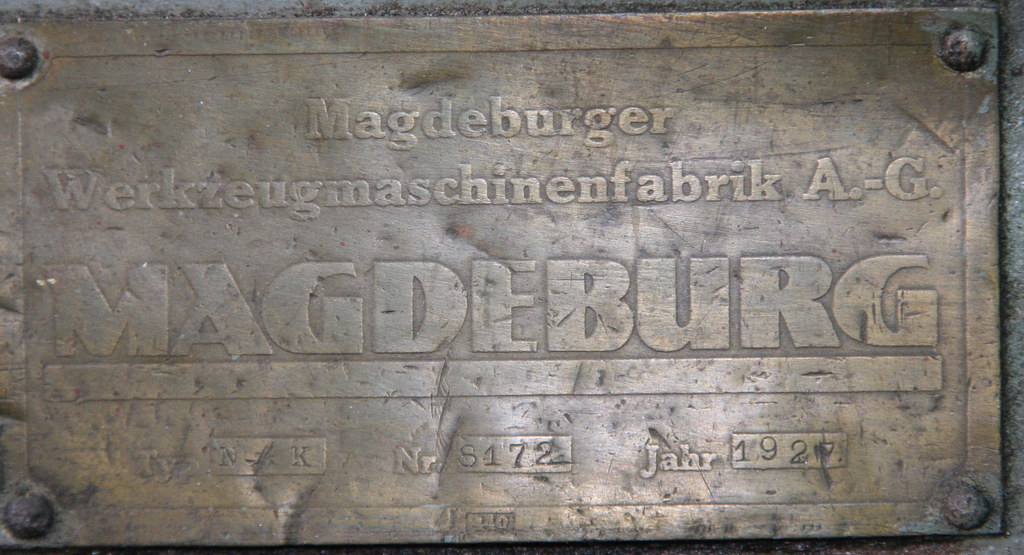

John Bertram & Sons - History | VintageMachinery.org

vintagemachinery.org