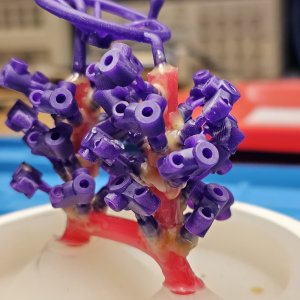

I finaly had some success with lost resin investment casting. This is like lost wax investment casting, however the pattern instead of being was is a special castable 3D printing resin.

Been at it for 2 years, each attempt takes so much time and there as so many variables; what resin, what printer exposure settings, what curring process, what metal, what burnout, what investment, what mixture etc etc. Very tedious and lots of blind alleys. But on the weekend, success!

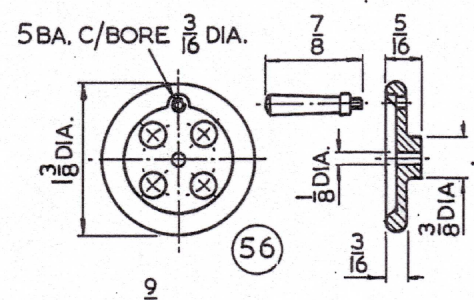

The main subject is the reversing handwheel for a Stuart Triple Expansion Marine Engine. The one on the drawings did not do the engine justice imo.

Two years of heartbreaking attemps (each one takes Friday - Sunday and is a lot of effort). I'd get close, but too many surface flaws. I can do a perfect lost wax casting, but the resin behaves differently.

That is a lot of attempts!!

I tried a new resin on the weekend, X-one resin which is not cured with UV light.

'

Keep your fingers crossed

Well, finally! They didn't all turn out great but one did and the results are better than anything so far. Most of the rest suffered from ( I realized after) a poor tree layout. It is being vacuum cast, but there are limits to how much it will run up hill.

Been at it for 2 years, each attempt takes so much time and there as so many variables; what resin, what printer exposure settings, what curring process, what metal, what burnout, what investment, what mixture etc etc. Very tedious and lots of blind alleys. But on the weekend, success!

The main subject is the reversing handwheel for a Stuart Triple Expansion Marine Engine. The one on the drawings did not do the engine justice imo.

Two years of heartbreaking attemps (each one takes Friday - Sunday and is a lot of effort). I'd get close, but too many surface flaws. I can do a perfect lost wax casting, but the resin behaves differently.

That is a lot of attempts!!

I tried a new resin on the weekend, X-one resin which is not cured with UV light.

'

Keep your fingers crossed

Well, finally! They didn't all turn out great but one did and the results are better than anything so far. Most of the rest suffered from ( I realized after) a poor tree layout. It is being vacuum cast, but there are limits to how much it will run up hill.