Tobho Mott

Active Member

A new client in Montreal needs 2 of these to attach and support a bed frame to a strut trolley for a pulley-bed system.

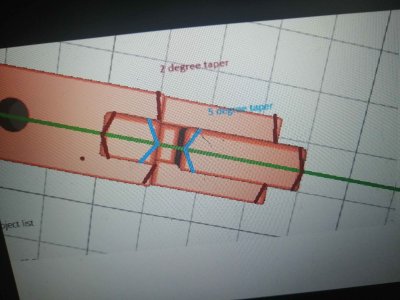

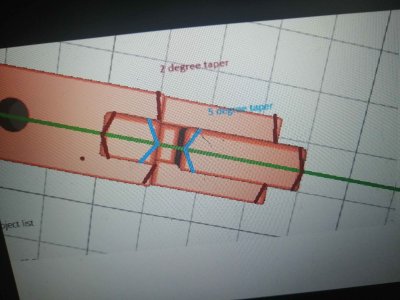

They are working with a CAD guy and sent me the 3d model to look at, so that I could let them know what needs to be changed to turn their model into a usable foundry pattern. Add draft here, fillets there, no on your budget and for this part you're actually better off drilling out those tiny cores than having me cast them in place, etc.

After multiple iterations where the draft was reversed or applied along the wrong axis...

Or fillets were put on the edges of the split pattern's parting line for some reason...

...or the dimensions were just wrong...

...I decided to try and figure out enough Freecad to model it myself. First day I was able to get it all done except for 3 fillets that the software just wouldn't cooperate on

...but, that is why we have bondo!

Just about ready to mold up now. If only the temperature would warm up a little, this is definitely not 'stick your bare fingers in frozen oily sand for an extended period' weather!

Jeff

They are working with a CAD guy and sent me the 3d model to look at, so that I could let them know what needs to be changed to turn their model into a usable foundry pattern. Add draft here, fillets there, no on your budget and for this part you're actually better off drilling out those tiny cores than having me cast them in place, etc.

After multiple iterations where the draft was reversed or applied along the wrong axis...

Or fillets were put on the edges of the split pattern's parting line for some reason...

...or the dimensions were just wrong...

...I decided to try and figure out enough Freecad to model it myself. First day I was able to get it all done except for 3 fillets that the software just wouldn't cooperate on

...but, that is why we have bondo!

Just about ready to mold up now. If only the temperature would warm up a little, this is definitely not 'stick your bare fingers in frozen oily sand for an extended period' weather!

Jeff