MashingMetal

Active Member

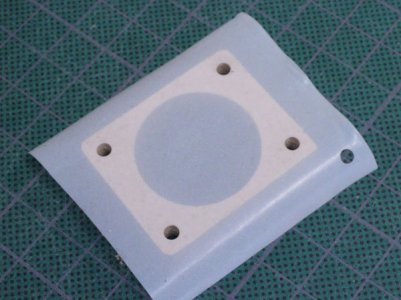

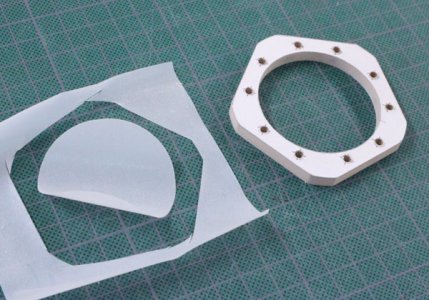

I am hoping someone more familiar with gasket material can help me. The seals are 0.001 in thickness for the caps use some sort of Mylar? I was hoping to make the new seals as the rebuild kits are $$$. I am setting up an inexpensive mixer for industrial finishes, yes it will br grounded.

Thanks!

Thanks!