FatherWes

Wes

I don't think I can attach a link, but there's potentially a heck of a good deal on a compressor at BCauction.ca auction number: A248776

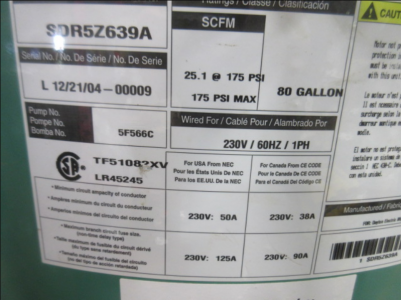

It's a Speedaire, Air Compressor: 7.5 HP, 25.1 CFM @ 175 psi

Too big for my needs (and power supply), but for someone with the need and power, this could be a great buy. Current bid is $898.88,

The bad news, Auction closes at 19:05 Pacific time. Sorry for the short notice, but I saw the auction a couple minutes ago.

It's a Speedaire, Air Compressor: 7.5 HP, 25.1 CFM @ 175 psi

Too big for my needs (and power supply), but for someone with the need and power, this could be a great buy. Current bid is $898.88,

The bad news, Auction closes at 19:05 Pacific time. Sorry for the short notice, but I saw the auction a couple minutes ago.