Downwindtracker2

Super User

Good Morning, I hope this finds you well after last night's victory.

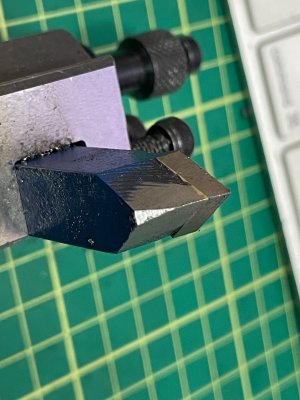

A question at the pointy end for experts.. Yesterday I was looking for a grind that gave a good surface finish .(aren't we all) So I honed a bit carefully.I was happy enough with the sharp. It wasn't one I had ground, rather an estate auction pick up. Just for background I spun the 5/8" CRS for 80sfm with, .005" travel. I had weld at the tip, when I knocked it off I could see deposits on the face. It was a good Armstrong brand HSS bit. I used Gunk brand high sulfur cutting oil.

How do I avoid the welding, I'm set up coolant, but don't use it.

A question at the pointy end for experts.. Yesterday I was looking for a grind that gave a good surface finish .(aren't we all) So I honed a bit carefully.I was happy enough with the sharp. It wasn't one I had ground, rather an estate auction pick up. Just for background I spun the 5/8" CRS for 80sfm with, .005" travel. I had weld at the tip, when I knocked it off I could see deposits on the face. It was a good Armstrong brand HSS bit. I used Gunk brand high sulfur cutting oil.

How do I avoid the welding, I'm set up coolant, but don't use it.