Engmaxx

(Michael)

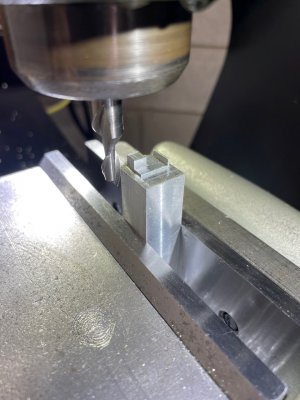

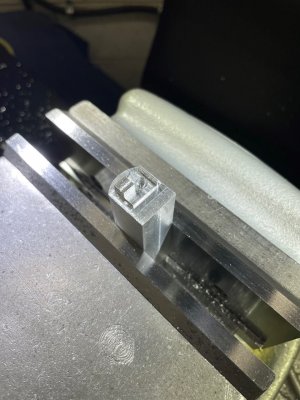

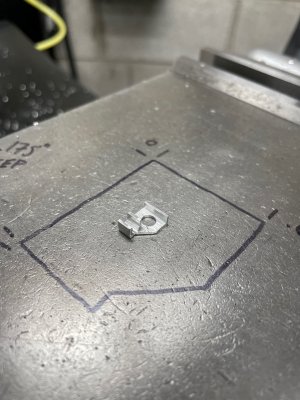

Broken throttle arm plastic bracket on my old Johnson. Wouldn't justify $55 for a NOS replacement. I made it instead. Works like the original and I can make it again if needed. Enjoy the fabrication porn or not!

Attachments

-

Outboard Bracket 03.jpg252 KB · Views: 33

Outboard Bracket 03.jpg252 KB · Views: 33 -

Outboard Bracket 04.jpg227 KB · Views: 32

Outboard Bracket 04.jpg227 KB · Views: 32 -

Outboard Bracket 05.jpg295.2 KB · Views: 28

Outboard Bracket 05.jpg295.2 KB · Views: 28 -

Outboard Bracket 06.jpg249.4 KB · Views: 30

Outboard Bracket 06.jpg249.4 KB · Views: 30 -

Outboard Bracket 07.jpg304.6 KB · Views: 30

Outboard Bracket 07.jpg304.6 KB · Views: 30 -

Outboard Bracket 09.jpg314.1 KB · Views: 31

Outboard Bracket 09.jpg314.1 KB · Views: 31 -

Outboard Bracket 12.jpg312.1 KB · Views: 30

Outboard Bracket 12.jpg312.1 KB · Views: 30 -

Outboard Bracket 13.jpg252.8 KB · Views: 37

Outboard Bracket 13.jpg252.8 KB · Views: 37