How about tips, tricks, fails & things we do to parts AFTER they are printed?

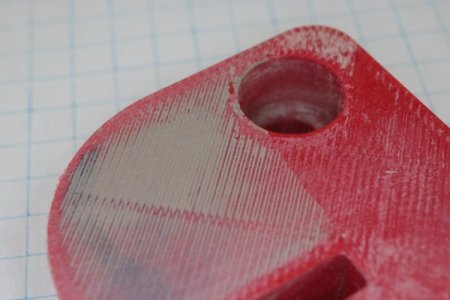

I'll start with this one. One of the things I want to do is make plugs or molds from 3D parts to then make composite parts The typical print striations & plate texture is not conducive to a slick finish so just messing around with common autobody supplies. I picked up this 1K putty, a brand I hadn't used before & spread it into some test surfaces just to see how it would fill and hold. This is generic PLA. Actually quite impressed. I thought it would flake off but adhesion was quite good. It sands predictably. I don't have any catalyzed 'Bondo' to try. Not sure if the styrene would play well but many thinners I wiped on PLA didn't affect it except acetone which does soften it slightly.

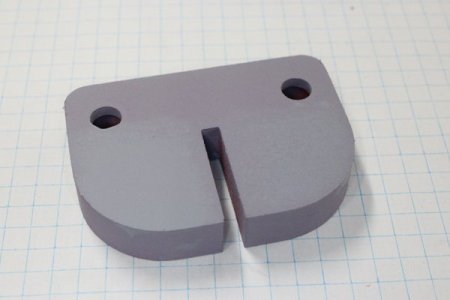

You just have to watch sanding into the plastic itself because it exposes that kind of what I call 'microscopic carpet' texture. The round piece had more magnified 3DP stair stepping due to the bevel print angle. You can see a test coat of white Tamiya primer intended for plastic models, just had it handy. That stuck well too. The grey is primer is regular Auto 1K. Again, no problem curing, or bonding to the filler or bare 3DP. I gave it a pre-wipe of paint prep which didn't affect PLA.

Casting soft molds like silicone from parts like these would be a no-brainer IMO. Hard molds are more challenging as they adhere much stronger to finishes even with proper mold release systems. Anyways, thats down the road.

I'll start with this one. One of the things I want to do is make plugs or molds from 3D parts to then make composite parts The typical print striations & plate texture is not conducive to a slick finish so just messing around with common autobody supplies. I picked up this 1K putty, a brand I hadn't used before & spread it into some test surfaces just to see how it would fill and hold. This is generic PLA. Actually quite impressed. I thought it would flake off but adhesion was quite good. It sands predictably. I don't have any catalyzed 'Bondo' to try. Not sure if the styrene would play well but many thinners I wiped on PLA didn't affect it except acetone which does soften it slightly.

You just have to watch sanding into the plastic itself because it exposes that kind of what I call 'microscopic carpet' texture. The round piece had more magnified 3DP stair stepping due to the bevel print angle. You can see a test coat of white Tamiya primer intended for plastic models, just had it handy. That stuck well too. The grey is primer is regular Auto 1K. Again, no problem curing, or bonding to the filler or bare 3DP. I gave it a pre-wipe of paint prep which didn't affect PLA.

Casting soft molds like silicone from parts like these would be a no-brainer IMO. Hard molds are more challenging as they adhere much stronger to finishes even with proper mold release systems. Anyways, thats down the road.