grease monkey

if ain't broke, you're not trying hard enough!

so I posed a query online, how to convert 3phase power to single phase, or more to the point, how to run a 3 phase motor on single phase residential power, couple different ways,

1- the expensive route is to install 3 phase power into your home, (like my cousin did, WOW, what I price, and he had to disconnect is current single phase to his house and feed it from his new 3 phase service in his shop, guy has transformers all over the place), he's more than $24,000 into this, but runs a full CNC shop now from home

2- the the phase converter route come in 2 forms, a motor big enough for your load with the output shaft removed so you cant run loads on it and a control unit, or a fancy resistor load bank with its control board,

3- install a single phase motor, but if you're like me and my mill, the output shaft of my motor was something very specific to my mill and well, only available from manufacturer- if they make one, which sadly mine did not, so..... if your so inclined, like I've at least seen 1 guy on here do, he modified a motor to suit.

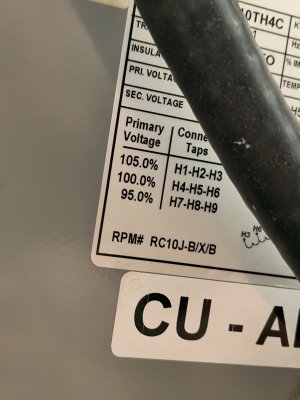

4- take your original motor to a rewind shop and have them rewind to a lesser voltage, my mill came 575v, I had them rewind the motor for 230v, still 3 phase, but a lesser voltage, and then install a vfd drive to use wizardry to produce the 3 phase, and voila! motor rewind cost me $1150 in London Ontario, vfd I found used for $150, done. manufacturer wanted $1900 for a 230v 3 phase motor and it was out of stock, no telling when they would get one. so I'm still money ahead

hope this helps!

1- the expensive route is to install 3 phase power into your home, (like my cousin did, WOW, what I price, and he had to disconnect is current single phase to his house and feed it from his new 3 phase service in his shop, guy has transformers all over the place), he's more than $24,000 into this, but runs a full CNC shop now from home

2- the the phase converter route come in 2 forms, a motor big enough for your load with the output shaft removed so you cant run loads on it and a control unit, or a fancy resistor load bank with its control board,

3- install a single phase motor, but if you're like me and my mill, the output shaft of my motor was something very specific to my mill and well, only available from manufacturer- if they make one, which sadly mine did not, so..... if your so inclined, like I've at least seen 1 guy on here do, he modified a motor to suit.

4- take your original motor to a rewind shop and have them rewind to a lesser voltage, my mill came 575v, I had them rewind the motor for 230v, still 3 phase, but a lesser voltage, and then install a vfd drive to use wizardry to produce the 3 phase, and voila! motor rewind cost me $1150 in London Ontario, vfd I found used for $150, done. manufacturer wanted $1900 for a 230v 3 phase motor and it was out of stock, no telling when they would get one. so I'm still money ahead

hope this helps!