TorontoBuilder

Ultra Member

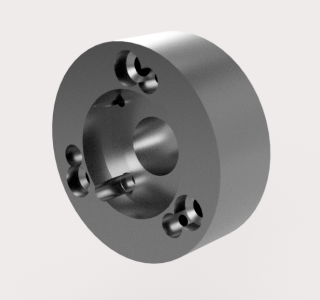

I want to make a D1-3 to stronghold chuck adapter since Oneway only makes adapters for screw mount spindles.

I'm not interested in a debate (too much anyways) on the advisability of turning wood on a metal lathe, I more wish to know if this may be unsafe or lacking good alignment.

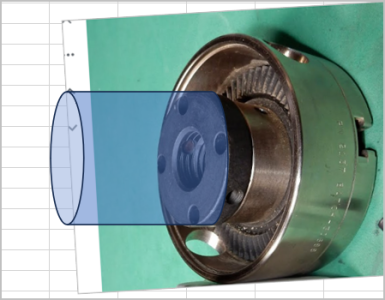

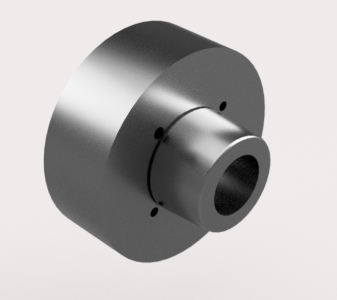

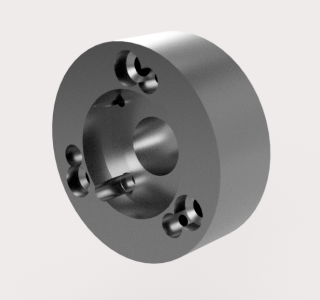

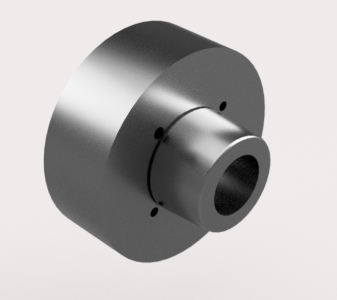

The stronghold chucks mount on a 1" long spigot with a 3+ degree taper. The chuck is secured by two opposing M5 screws from the rear of the adapter. These two holes are slightly over sized and unthreaded.

Two M5 threaded holes offset 90 degrees allow screws to be inserted to push the chuck off the spigot for removal.

Sadly, all four holes land right in the D1-3 spindle taper surface. Two of the holes are larger to accommodate the socket screw head. I can use grub screws in the threaded holes to push off the stronghold chuck and therefore have a smaller notch in my tapered seating surface. Still there will be 4 evenly spaced notches in my tapered surface.

Any foreseeable issues that make this a non-starter?

I'll only be using this on the chippie so I cant throw any wide heavy bowls due to the small lathe size. I more want to turn tool handles, small round boxes, and small bowls and decorative wood items

I'm not interested in a debate (too much anyways) on the advisability of turning wood on a metal lathe, I more wish to know if this may be unsafe or lacking good alignment.

The stronghold chucks mount on a 1" long spigot with a 3+ degree taper. The chuck is secured by two opposing M5 screws from the rear of the adapter. These two holes are slightly over sized and unthreaded.

Two M5 threaded holes offset 90 degrees allow screws to be inserted to push the chuck off the spigot for removal.

Sadly, all four holes land right in the D1-3 spindle taper surface. Two of the holes are larger to accommodate the socket screw head. I can use grub screws in the threaded holes to push off the stronghold chuck and therefore have a smaller notch in my tapered seating surface. Still there will be 4 evenly spaced notches in my tapered surface.

Any foreseeable issues that make this a non-starter?

I'll only be using this on the chippie so I cant throw any wide heavy bowls due to the small lathe size. I more want to turn tool handles, small round boxes, and small bowls and decorative wood items