GummyMonster

Ken

Morning everyone,

Well, my lathe and milling machine are finally in Canada. Somewhere between Vancouver and their new home. Waiting impatiently.

Anyway,

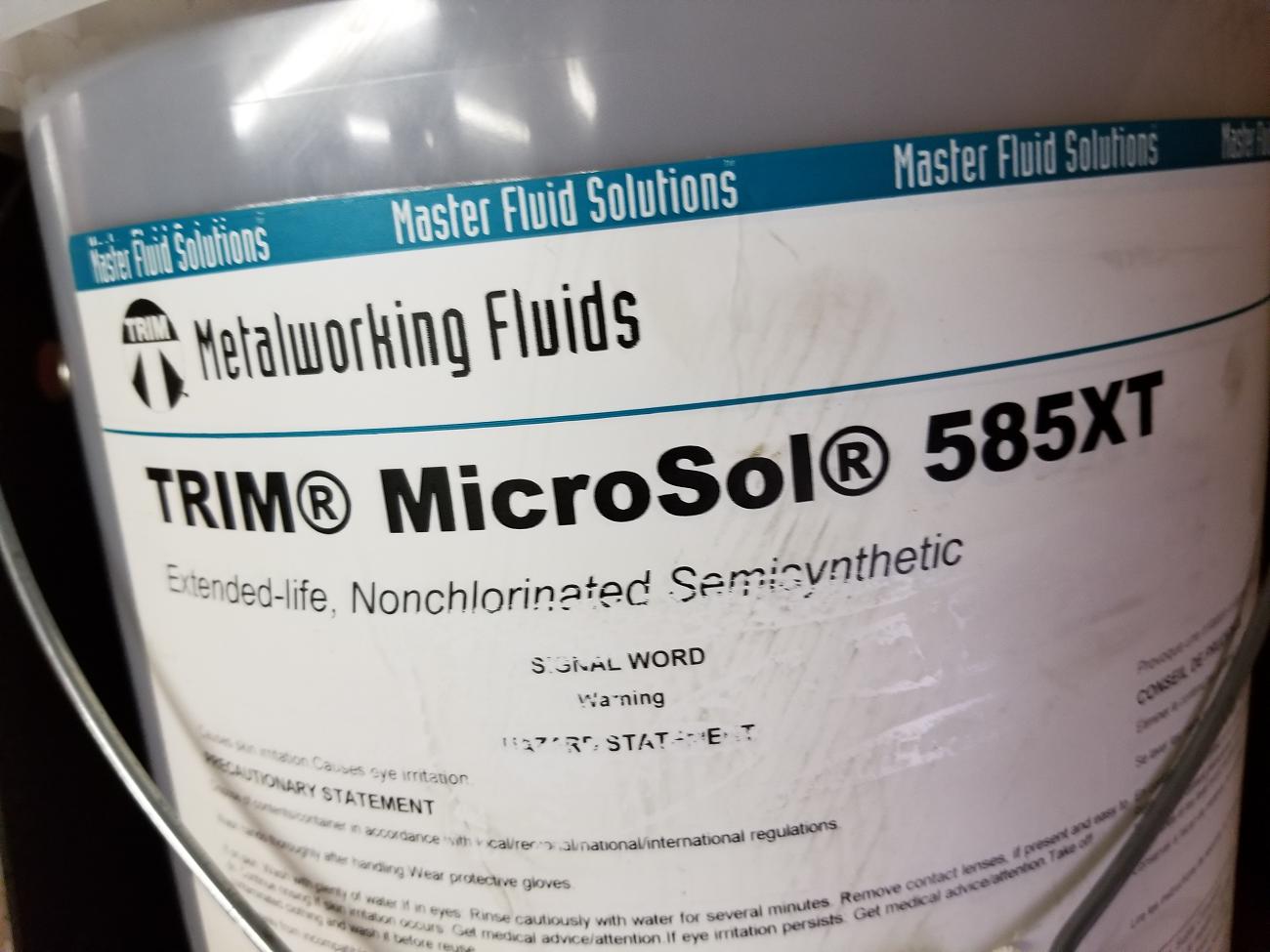

I bought some cutting fluid at Princess Auto the other day. I was kinda hurrying and I didn't read the front of the jug. Turns out it's water soluble cutting fluid.

Anyone else use this? It says to mix it between 5:1 and 20:1 water/fluid mix.

Maybe it's fine, but it seems odd to me. At 20:1, you're using almost straight water.

I used it to drill through a truck hitch and it seemed ok, but it seemed like it was just washing away the chips and swirls more than anything.

I just wanted to see what you experienced folks think before using it on anything more important, precise. And I don't want to be damaging the drill bits either.

Thanks for any input you can give,

Ken

Well, my lathe and milling machine are finally in Canada. Somewhere between Vancouver and their new home. Waiting impatiently.

Anyway,

I bought some cutting fluid at Princess Auto the other day. I was kinda hurrying and I didn't read the front of the jug. Turns out it's water soluble cutting fluid.

Anyone else use this? It says to mix it between 5:1 and 20:1 water/fluid mix.

Maybe it's fine, but it seems odd to me. At 20:1, you're using almost straight water.

I used it to drill through a truck hitch and it seemed ok, but it seemed like it was just washing away the chips and swirls more than anything.

I just wanted to see what you experienced folks think before using it on anything more important, precise. And I don't want to be damaging the drill bits either.

Thanks for any input you can give,

Ken