-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wanted: Proxxon band saw

- Thread starter Janger

- Start date

I didn't realize that little fellah existed. What kind of metal cutting do you anticipate doing? My dream machine is a Hegner scroll saw based on what I see Clickspring (YouTube clockmaker) use. Scroll saws allow you outside & inside (piercing) cuts vs. bandsaw is only outside & more limited radius. But Hegners are crazy expensive although I've come close bidding on used ones.

I have a variable speed Dewalt scroll saw which I think is comparable power. I use it 99% for woodworking which it handles very well. It will do sheet metal with the appropriate 5" fretsaw (unpinned) jeweller blades. But my experience is metal cutting is just not pretty & I'm not exactly sure why. The arm mechanism doesn't seem all that different relative to blade movement. Its cast iron so plenty rigid. On thin metal, half the battle is keeping the surface from deflecting under cutting stroke. What I found best is using spray adhesive & laminate the metal onto 1/8" junk grade hardboard. Then use acetone to release the glue. But anything thicker than 1/16" soft metal seem to be very slow going. I don't know how Clickspring plows through thicker brass. Maybe there is something to the saw.

King is now the distributer for what used to be Excalibur scroll saws (now called Excelsior). From what I was told these were next in line behind Hegner (again spendy). But I have not used either to pass opinion. http://www.kingcanada.com/detail/16-professional-scroll-saw-XL-16/1143

My regular metal cutting bandsaw can go in upright position with a table attachment. I use that a lot. Cut out as much material as I can to save milling time, wear & tear.

I've also tried putting a jigsaw with metal blade in inverted position with home brew table. It cuts but lack of precision for sure. Consider a roughing tool.

I have a variable speed Dewalt scroll saw which I think is comparable power. I use it 99% for woodworking which it handles very well. It will do sheet metal with the appropriate 5" fretsaw (unpinned) jeweller blades. But my experience is metal cutting is just not pretty & I'm not exactly sure why. The arm mechanism doesn't seem all that different relative to blade movement. Its cast iron so plenty rigid. On thin metal, half the battle is keeping the surface from deflecting under cutting stroke. What I found best is using spray adhesive & laminate the metal onto 1/8" junk grade hardboard. Then use acetone to release the glue. But anything thicker than 1/16" soft metal seem to be very slow going. I don't know how Clickspring plows through thicker brass. Maybe there is something to the saw.

King is now the distributer for what used to be Excalibur scroll saws (now called Excelsior). From what I was told these were next in line behind Hegner (again spendy). But I have not used either to pass opinion. http://www.kingcanada.com/detail/16-professional-scroll-saw-XL-16/1143

My regular metal cutting bandsaw can go in upright position with a table attachment. I use that a lot. Cut out as much material as I can to save milling time, wear & tear.

I've also tried putting a jigsaw with metal blade in inverted position with home brew table. It cuts but lack of precision for sure. Consider a roughing tool.

I believe it's 400 strokes/min & stroke length is 3/4". So if I did my math right, that works out to 25 ft/min equivalent (400 strokes/min * 0.75 in/stroke /12 in/ft)

A bit of blurb in the user manual

http://www.dewalt.ca/en-ca/products/power-tools/saws/scroll-saws/20-variablespeed-scroll-saw/dw788

According to the link, Proxoon is 395 to 820 ft./minute with feedback control

https://www.amazon.ca/Proxxon-37172...id=1510697360&sr=8-4&keywords=proxxon+bandsaw

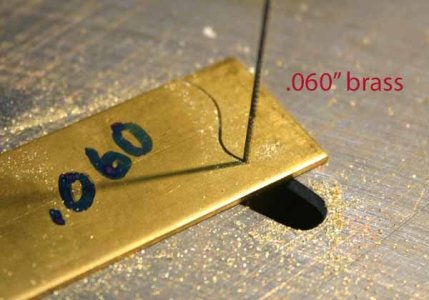

Here are some sample cuts on copper & brass sheet I had handy using a new jewellers blade as shown. The teeth are 1-way so only cuts on down stroke. It's faster than you could cut with a jeweller frame (and a lot less fatiguing). If she is doing harder alloys or much thicker or wants faster cutting, this might be the transition point to a bigger/different saw. Hard to say without knowing the range of materials.

A bit of blurb in the user manual

http://www.dewalt.ca/en-ca/products/power-tools/saws/scroll-saws/20-variablespeed-scroll-saw/dw788

According to the link, Proxoon is 395 to 820 ft./minute with feedback control

https://www.amazon.ca/Proxxon-37172...id=1510697360&sr=8-4&keywords=proxxon+bandsaw

Here are some sample cuts on copper & brass sheet I had handy using a new jewellers blade as shown. The teeth are 1-way so only cuts on down stroke. It's faster than you could cut with a jeweller frame (and a lot less fatiguing). If she is doing harder alloys or much thicker or wants faster cutting, this might be the transition point to a bigger/different saw. Hard to say without knowing the range of materials.

Attachments

I’m looking for a proxxon bandsaw or similar - it’s for jewellery and must have a slow speed setting for metal. Wood ones are way too fast of course.

I have an old tabletop craftsman you can have. It runs quite slow. It needs tlc but it works. It takes 1/8" to 3/8" blades.

Regards

John

I finally re-found the link that was stuck in my mind. Low stroke speed, true linear sawing motion & using full extent of blade. Cool machine design concept but OMG <cough> the price! That's a Gucci tool even for the jewelers trade. http://www.knewconcepts.com/power.php