TorontoBuilder

Ultra Member

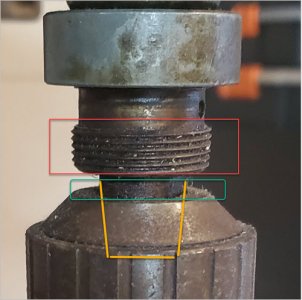

I need to disassemble my drill press so I can sand blast it in preparation for fresh paint, and to install a keyless chuck.

Sadly, the knurled nut and wedge that originally came with the DP when my grandfather bought it have long since disappeared. I'm surprised that the nut disappeared since it was installed above the chuck.

Anyway, I need a JT33 wedge set, even to just borrow one so I can remove the chuck and pull the spindle. Anyone between Toronto and Guelph got a set?

Sadly, the knurled nut and wedge that originally came with the DP when my grandfather bought it have long since disappeared. I'm surprised that the nut disappeared since it was installed above the chuck.

Anyway, I need a JT33 wedge set, even to just borrow one so I can remove the chuck and pull the spindle. Anyone between Toronto and Guelph got a set?