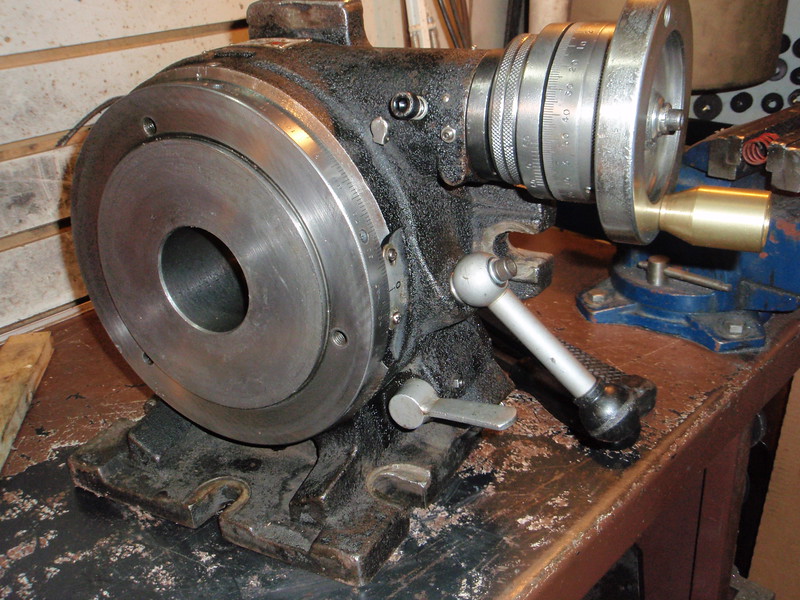

I bought this Vertex 8" "Super Spacer" used on Kijiji a few years ago. I paid $200 which I thought was pretty high until I looked at the price of a new one which sell for about $1000 USD without the chuck. It was pretty abused and pretty rusty and crusty on the inside. I completely disassembled it and assessed the damage. The worm gear was pretty worn and the thrust bearing on the input shaft was screwed. I bought a new bearing at a local bearing supply house for about $20 but had no luck finding a new worm gear at the time so I just re-assembled it after cleaning and lubing everything and it turned out to work very well even with all the wear on the worm gear because the backlash is adjustable.

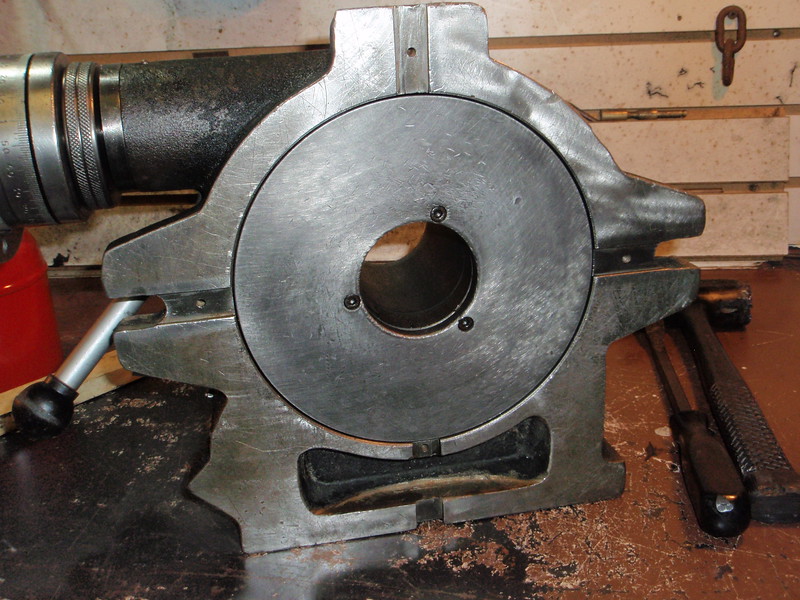

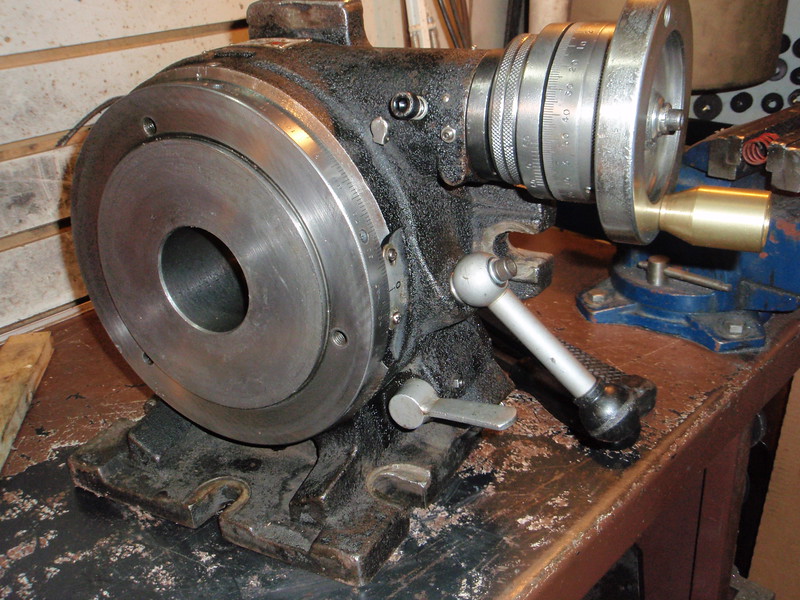

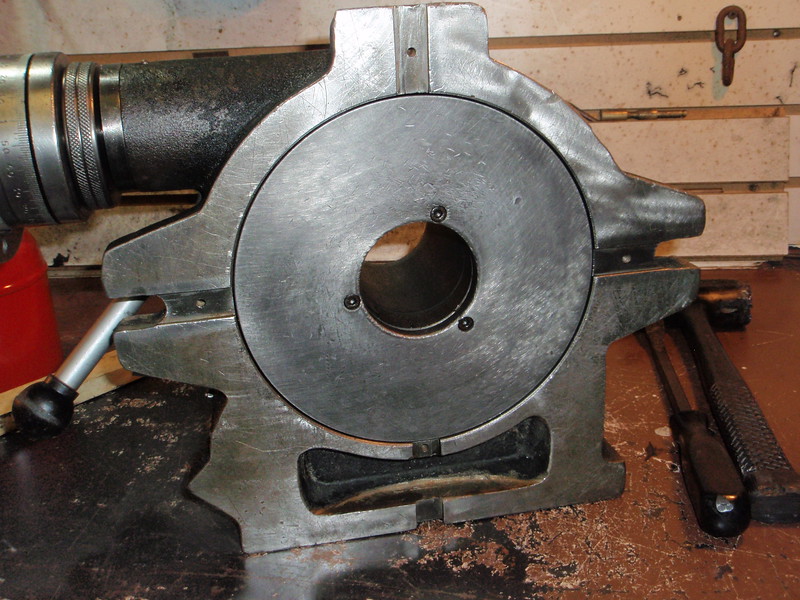

After disassembly and cleaning the main body and table look very nice.

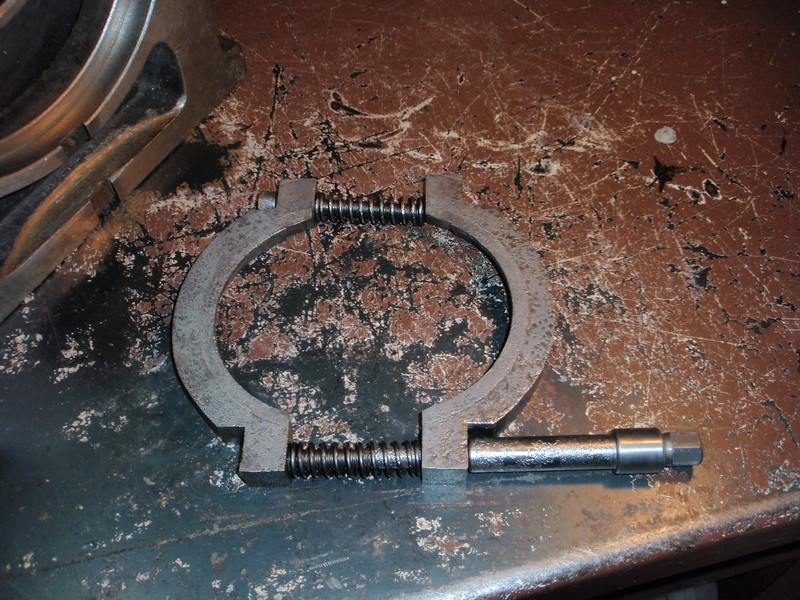

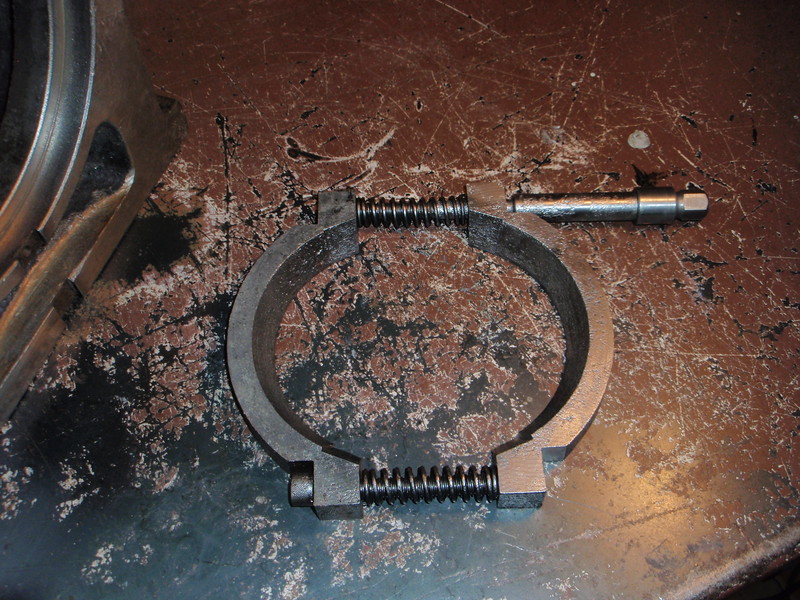

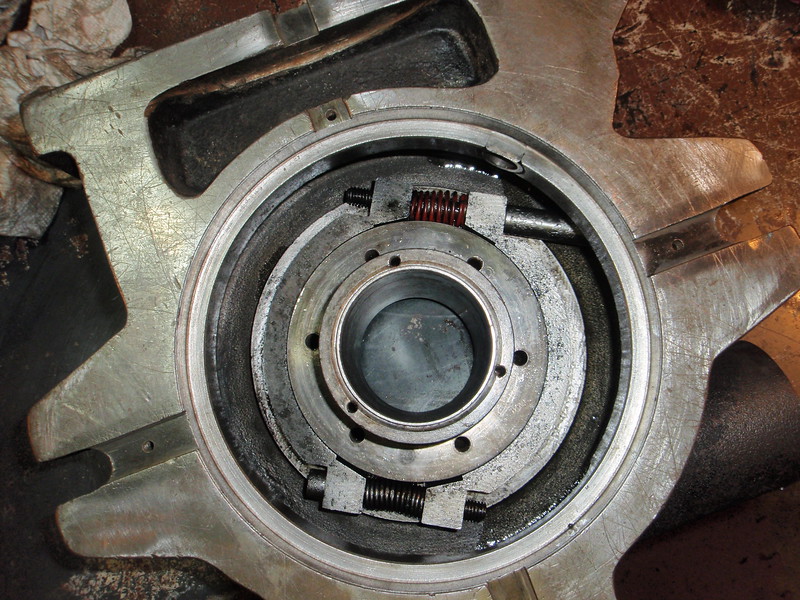

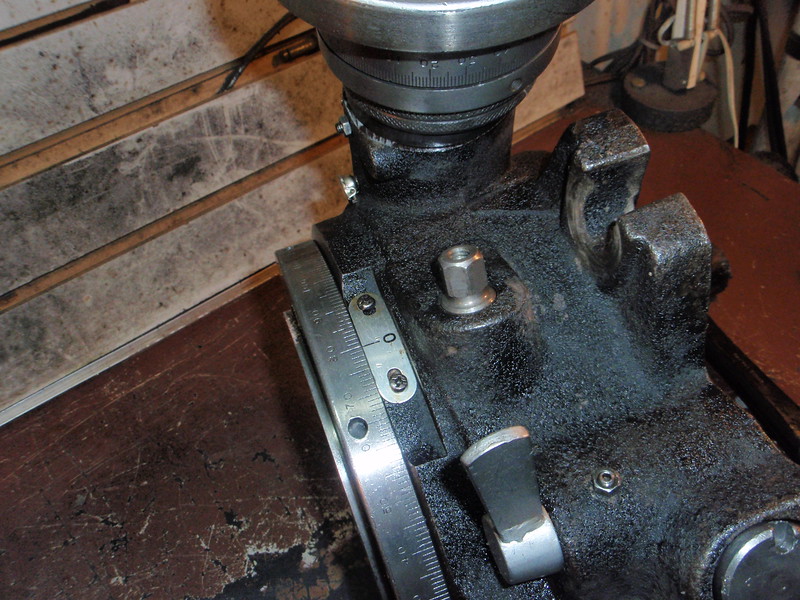

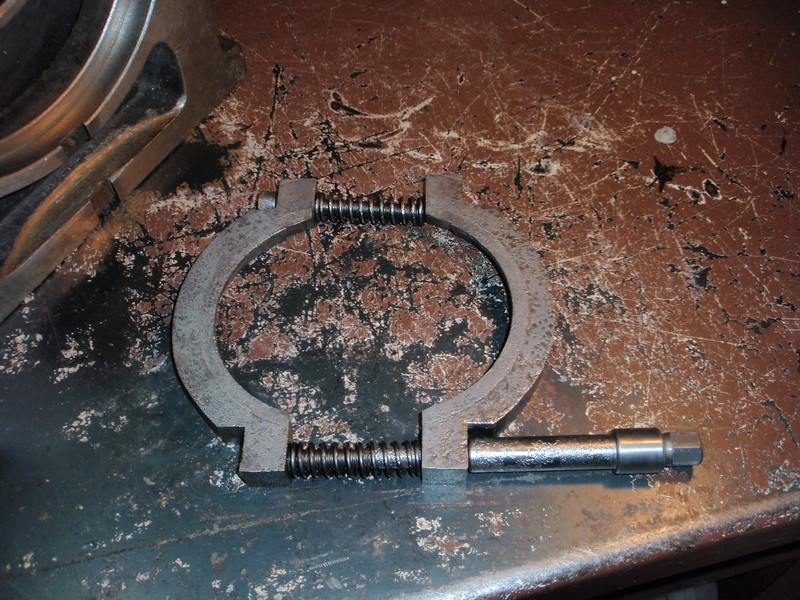

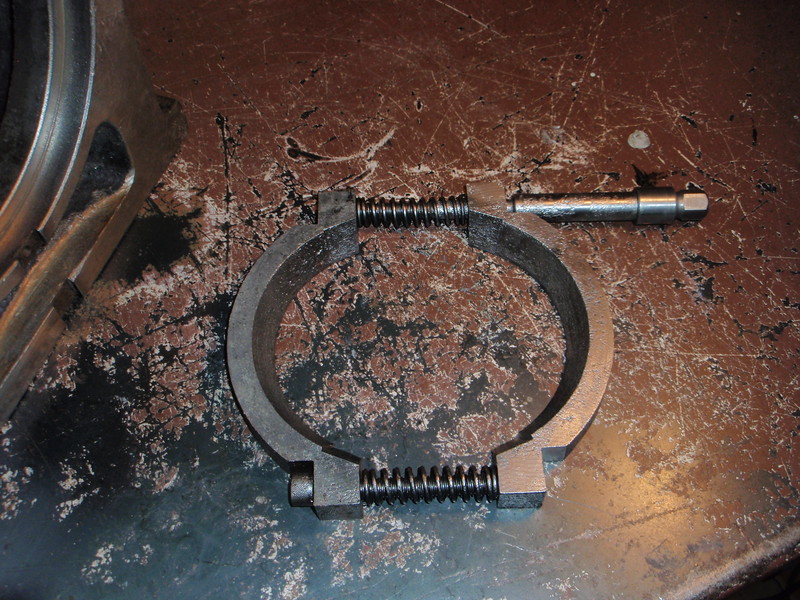

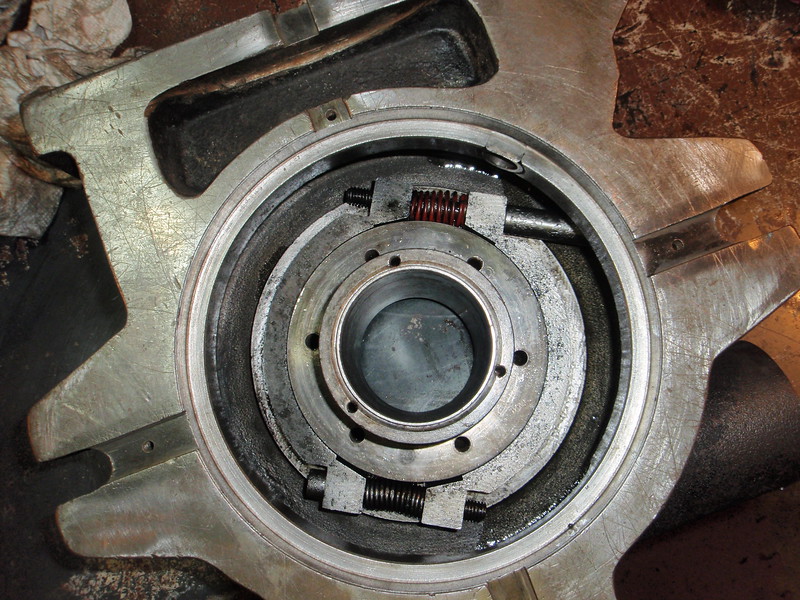

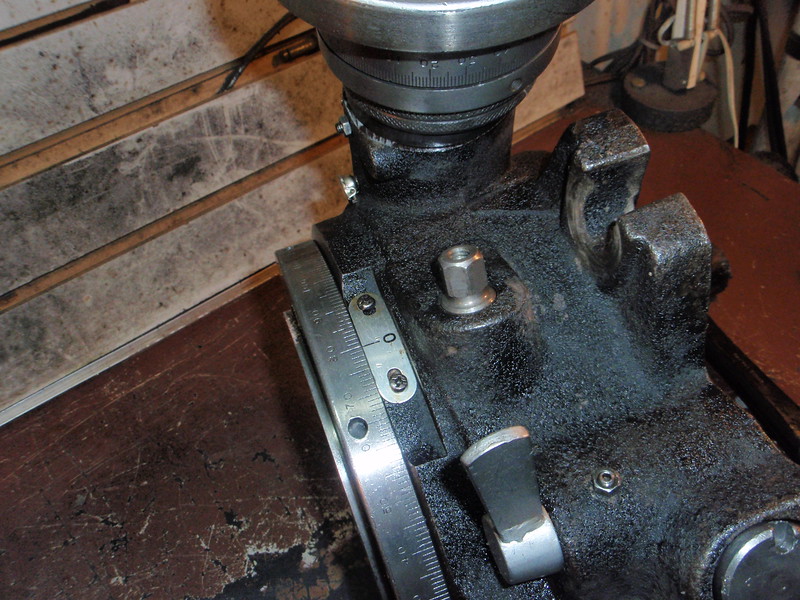

The cast iron brake shoes and hardware were very rusty but after bead blasting are perfectly usable. The tapered shape of the brake mechanism pulls the table back into hard contact with the body to stop rotation and remove any clearance between the table and the body.

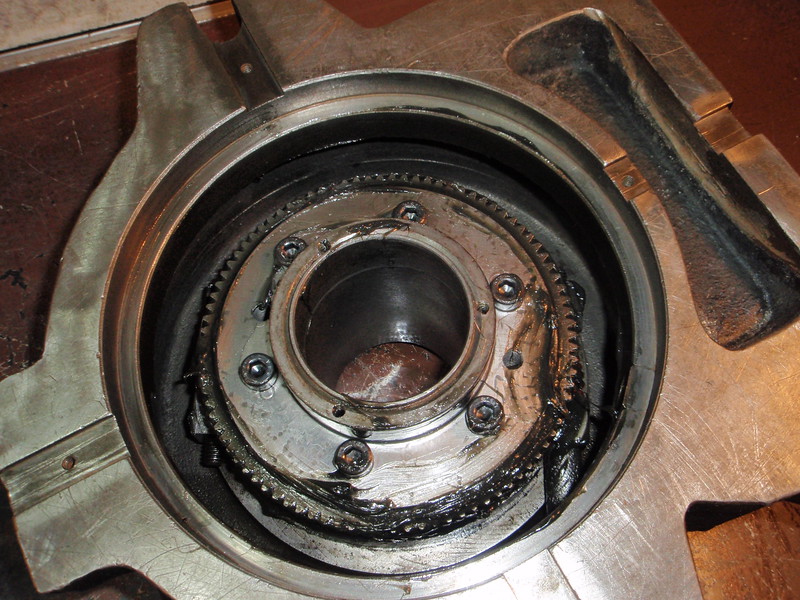

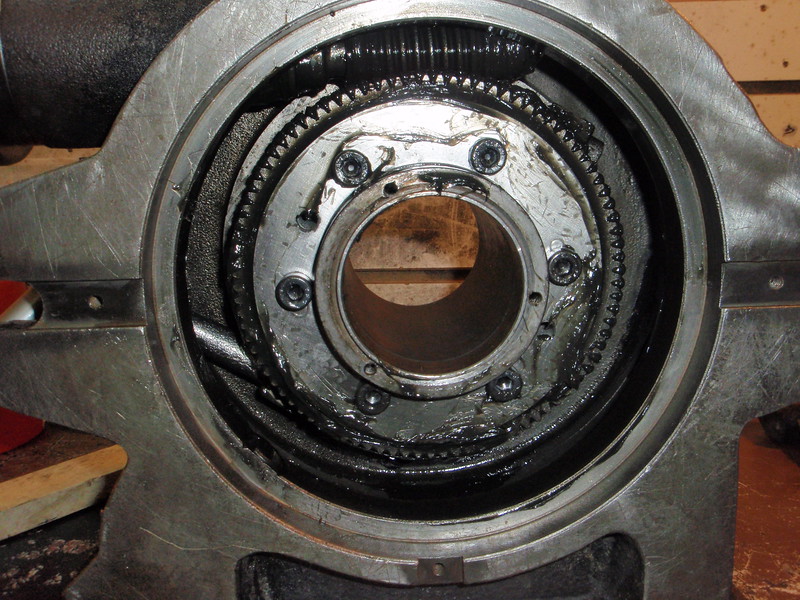

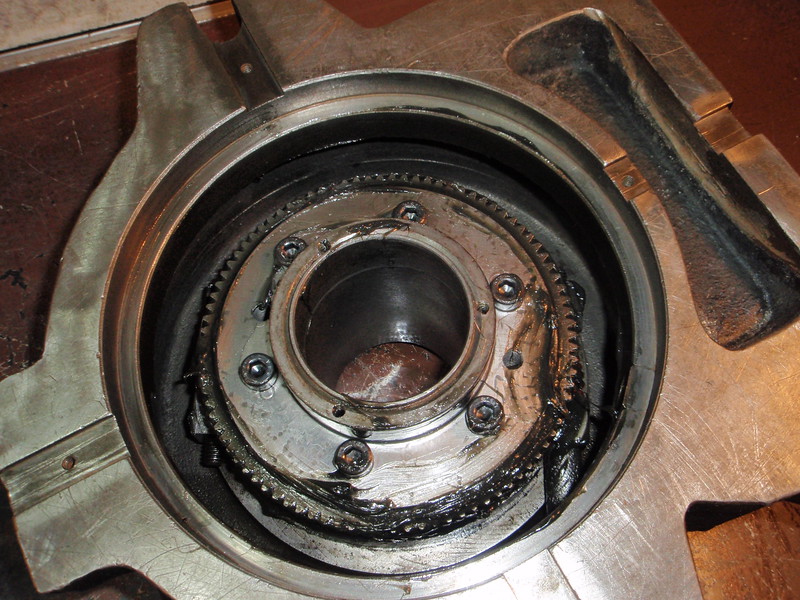

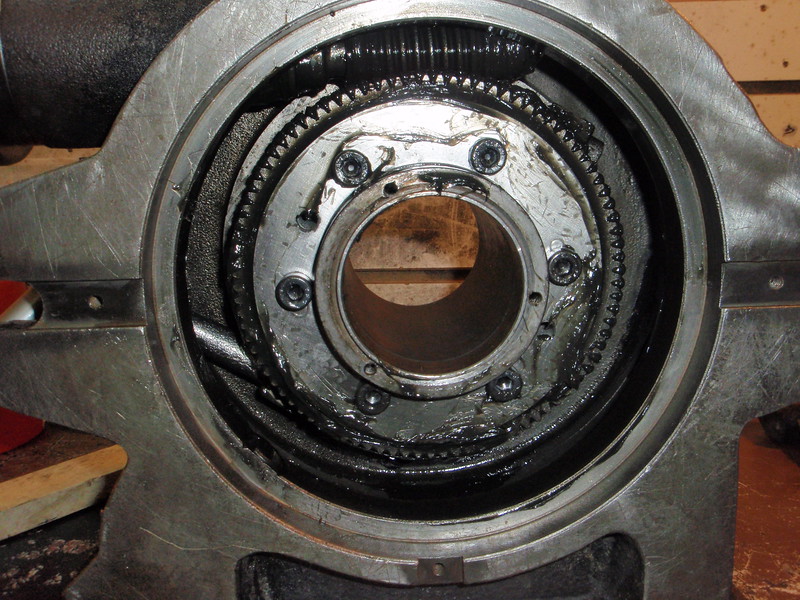

Here you can see just how badly the worm gear is worn, although I don't have a picture the appears to be not worn at all. There are 3 teeth that are very badly worn.

The rest are pretty worn but not completely screwed. It worked very smoothly like this and only had a small amount of backlash in the area with the 3 really bad teeth. As I said, I used it like this for about 3 years with good results.

The thrust bearing looked like this when I took it out but a new one was easily obtainable locally.

Lots of grease hid the wear well!

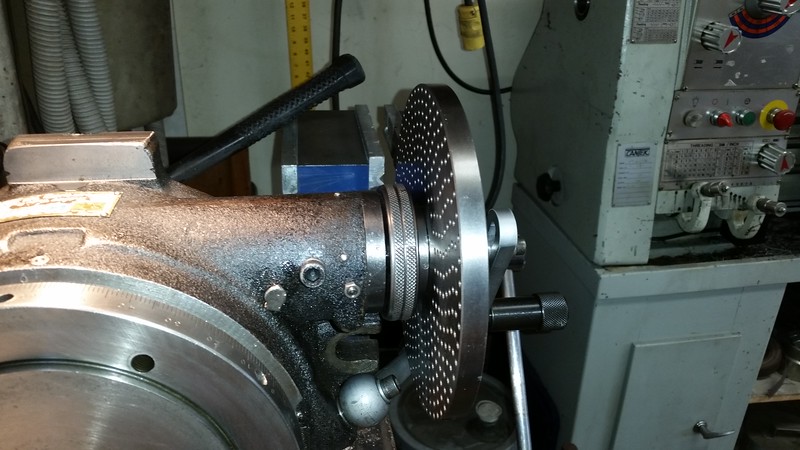

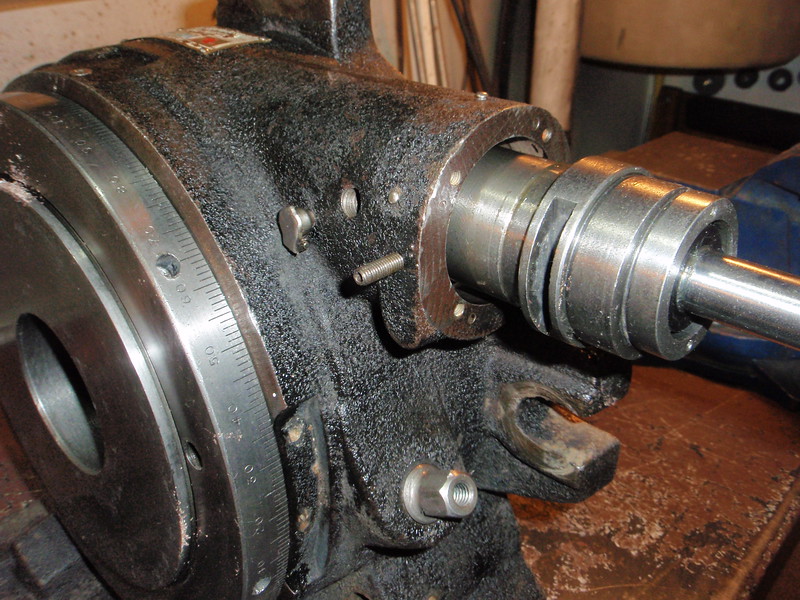

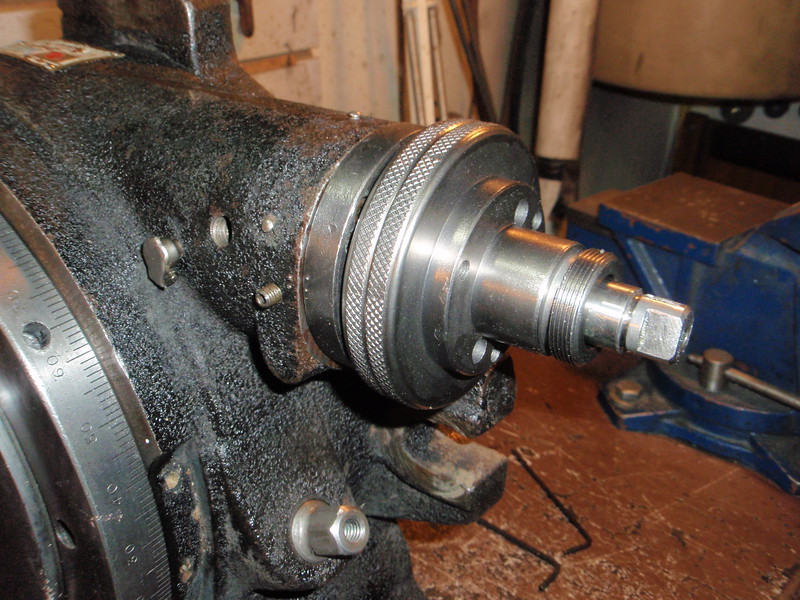

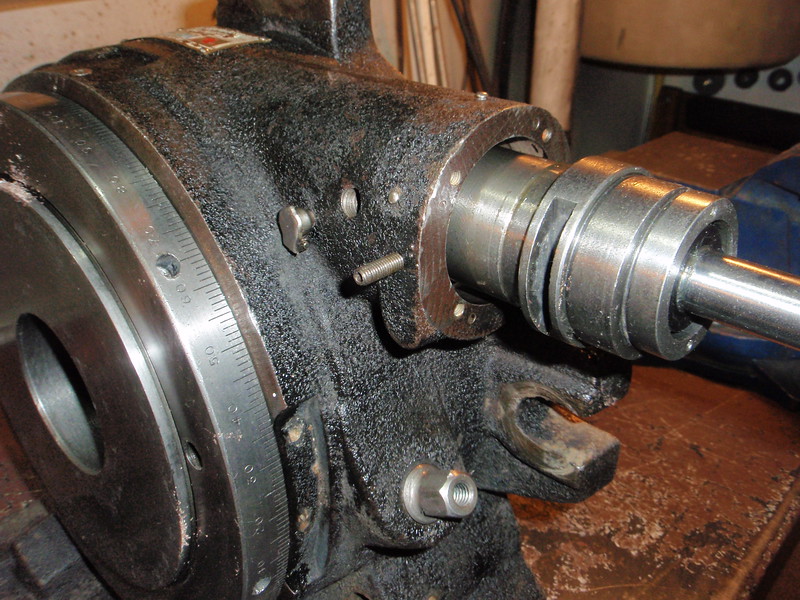

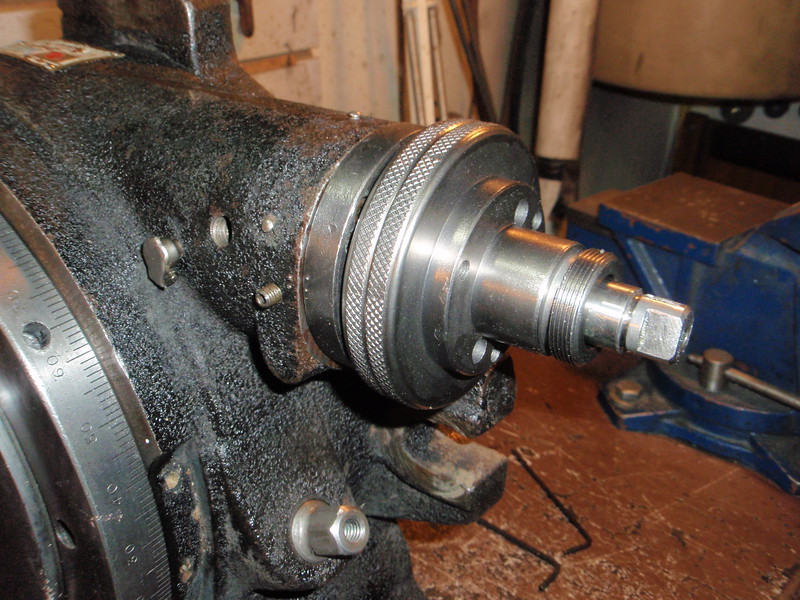

With new bearings on the input/pinion shaft I assembled all the cleaned up components.

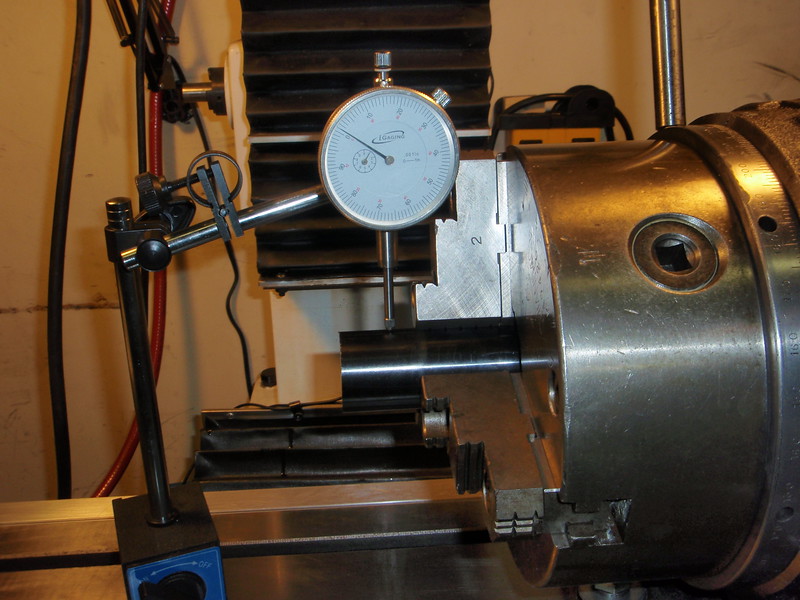

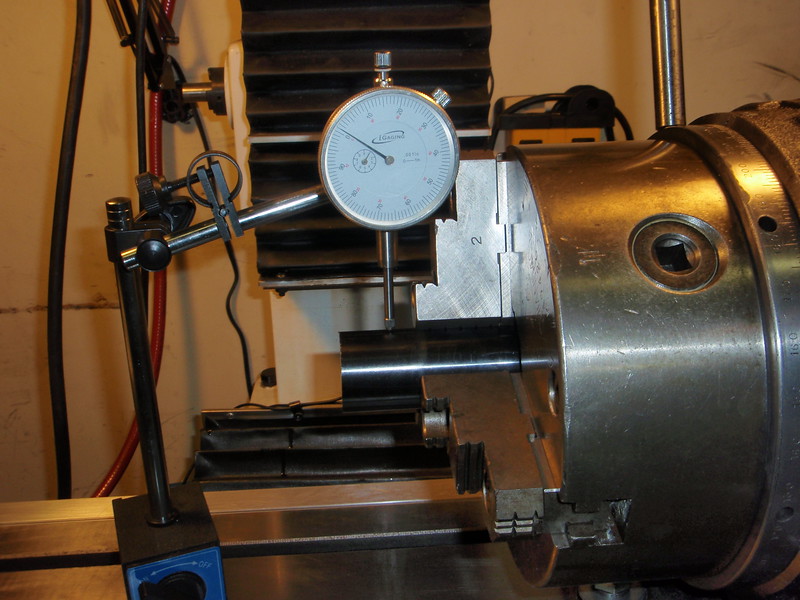

I checked the run-out with various rounds clamped in the chuck and it consistently show .001" or less.

After disassembly and cleaning the main body and table look very nice.

The cast iron brake shoes and hardware were very rusty but after bead blasting are perfectly usable. The tapered shape of the brake mechanism pulls the table back into hard contact with the body to stop rotation and remove any clearance between the table and the body.

Here you can see just how badly the worm gear is worn, although I don't have a picture the appears to be not worn at all. There are 3 teeth that are very badly worn.

The rest are pretty worn but not completely screwed. It worked very smoothly like this and only had a small amount of backlash in the area with the 3 really bad teeth. As I said, I used it like this for about 3 years with good results.

The thrust bearing looked like this when I took it out but a new one was easily obtainable locally.

Lots of grease hid the wear well!

With new bearings on the input/pinion shaft I assembled all the cleaned up components.

I checked the run-out with various rounds clamped in the chuck and it consistently show .001" or less.