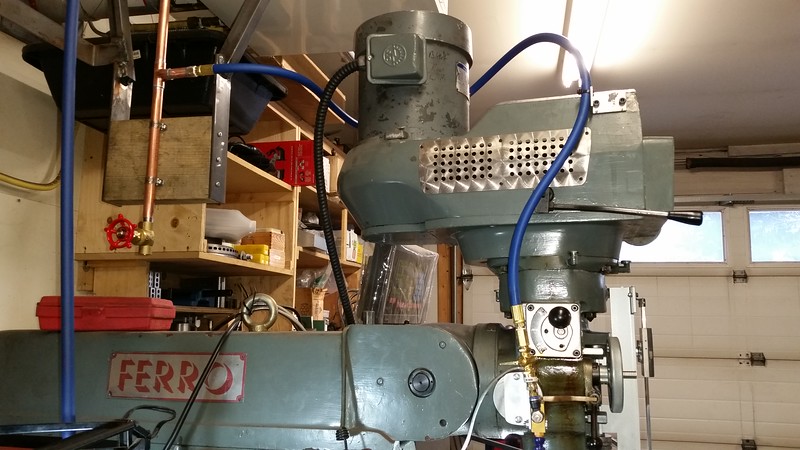

My little 20 gallon air compressor was just not cutting it when it came to using air impact tools. The max pressure was 110psi and the air tools weren't doing what I need them to. I shopped around and decided to take a chance buying this Chinese made 2 stage compressor with an 80 gallon tank. It's rated at 21 cfm at 180 psi. I'm not sure if that's accurate but it fills the tank to 180 psi from empty in 12 minutes. That's about the same amount of time it took my old compressor to fill the 20 gallon tank to 110 psi. I had to use the last 2 empty breaker slots in my panel for the 220 volt breaker so I guess I can't buy anymore big tools!

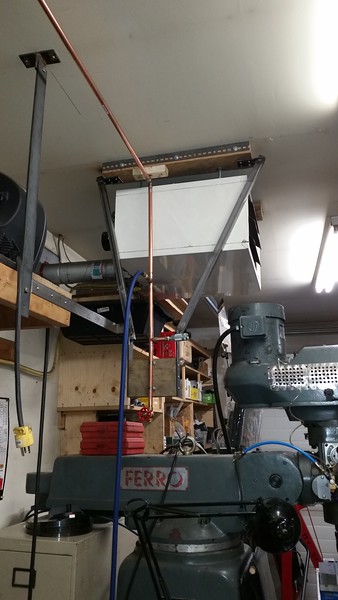

I had to modify some existing shelving to fit it into this corner but it fits like as glove and it easy to roll out away from the corner for servicing.

I had to modify some existing shelving to fit it into this corner but it fits like as glove and it easy to roll out away from the corner for servicing.