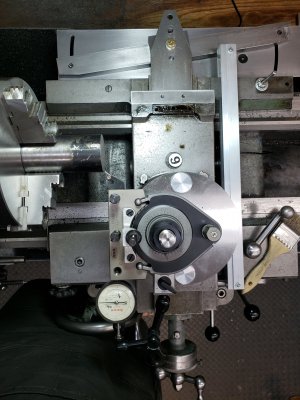

I'm doing a project at the moment which requires that I machine an 8° taper. But recently I've converted to a solid tool post mount for my lathe. I was too lazy to remove it and put the compound back on. So I decided to use the taper turning attachment and set up the required angle with a sine bar, gage blocks and DTI. When using the taper turning attachment, you let the crosslide follow the bar of the TTA, so you have to disengage the cross slide lead screw from it's nut. To control depth of cut, you turn the compound to 90°, and use it for that. Oh yeah, I'm not using the compound!! No problem. A little red neck, but it works. Just move the tool forward every pass. Loosen the tool holder screws, advance the tool, in this case 0.025" which you use a dial indicator, and tighten the screws and continue.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Taper Turning without a Compound

- Thread starter thestelster

- Start date

Nicely done. Although it does make me appreciate my South Bend Taper Attachment a bit more.I'm doing a project at the moment which requires that I machine an 8° taper.

So on that model / vintage SM they had not yet switched to a telescoping lead screw in the cross slide. It would make your life a lot easier if it had one since you are using a solid tool post. Good work-around in any case!When using the taper turning attachment, you let the crosslide follow the bar of the TTA, so you have to disengage the cross slide lead screw from it's nut.

Is that taper 8* total (4*/side) or 8*/side for a total of 16*?

Hi @RobinHoodSo on that model / vintage SM they had not yet switched to a telescoping lead screw in the cross slide. It would make your life a lot easier if it had one since you are using a solid tool post. Good work-around in any case!

Is that taper 8* total (4*/side) or 8*/side for a total of 16*?

I made the taper turning attachment, so I'm not familiar with that feature, but yes, that would be nice.

It's 8° per side. (ER collet....but I'm not making an ER collet.)

I remember you talking about that. Nice job.

Here is a cross section of what SM went to in their 1340 models (I am sure the bigger lathes are similar) when they introduced the telescoping cross slide lead screw. No need to disconnect the nut. Just set the TA, and switch the cross slide from normal ops to TA ops by tightening/backing off a big bolt at the RH rear of the cross slide.

Most other manufacturers who offer TAs have a similar arrangement if their cross slides are telescoping.

Here is a cross section of what SM went to in their 1340 models (I am sure the bigger lathes are similar) when they introduced the telescoping cross slide lead screw. No need to disconnect the nut. Just set the TA, and switch the cross slide from normal ops to TA ops by tightening/backing off a big bolt at the RH rear of the cross slide.

Most other manufacturers who offer TAs have a similar arrangement if their cross slides are telescoping.

Hmm...I'll have a look at those drawings later and see if I can incorporate it in my unit. Thank you Robin.I remember you talking about that. Nice job.

Here is a cross section of what SM went to in their 1340 models (I am sure the bigger lathes are similar) when they introduced the telescoping cross slide lead screw. No need to disconnect the nut. Just set the TA, and switch the cross slide from normal ops to TA ops by tightening/backing off a big bolt at the RH rear of the cross slide.

View attachment 27581

Most other manufacturers who offer TAs have a similar arrangement if their cross slides are telescoping.

Even though I had to resort to this method of advancing the tool when using the TTA, it's no big deal; a little inconvenient, but easily doable. And besides, how often are you using the TTA anyway? Of course if you have a DRO, and that tool holder is set in its tool library, you'll have to re-calibrate afterwards.Good problem solving. Yes, we must remember to add that detail to the solid tool post pros & cons list. How are you liking it so far from cutting standpoint?

In terms of rigidity, I'm not sure I notice a big difference. My lathe is pretty robust. But parting does seem better, of course it might be the placebo effect! And I do feel a little more confident taking 0.080" depth of cuts. What I definitely like, is that without the compound, it cleans up the right side of the toolpost. It allows easier access when the tailstock is up close to the carriage. Though I now use the drill chuck on the MULTIFIX QCTP for drilling/reaming. And only use the tailstock for holding a center.

And I do feel a little more confident taking 0.080" depth of cuts.

There is no Plinth that could ever enlarge my gonads to that level of guts!

You must have bow legs.

My voice goes up an octave at half that!

Maybe I'm just a big hairy wuss.

Hi Darren, the 0.080" is the listed max depth of cut for the inserts I'm using, which are actually finishers. I actually plan on getting some roughers which can do double that depth. But then, like you said, we might be approaching max hp rating, depending on material I'm turning, unless we reduce the feed rate.0.080" is not a heavy cut , especially for an SM 16" machine. Did it have trouble before the solid toolpost? On my 10" Emco, 030 -040 was about max before I built a solid toolpost. It would do 060 easily after, with HP being the limiting factor.

Baldor 5hp, 220v 3P through a VFD.Ah ok, I get ya now. I thought maybe there was something I was missing about the setup. How many ponies do you have?

0.080" is not a heavy cut , especially for an SM 16" machine. Did it have trouble before the solid toolpost? On my 10" Emco, 030 -040 was about max before I built a solid toolpost. It would do 060 easily after, with HP being the limiting factor.

My lathe is a 14x40 with a 2HP single phase motor. A three phase 3HP with VFD is in the plans. I have the VFD, I just need to find a 3HP VFD ready motor in the right frame at a decent price. Then it's time for a DRO..... Way too much fun for an old man.

Even if mine could do 80, I'd prolly never try it. I prefer to walk straight.

Well, this is what 0.080" depth of cut, @0.010"/rev. feed rate.

Just had to try it didn't you....

Is it even possible for you to walk straight ??

I haven't walked straight in a long time. Hunched over a work bench or lathe for years!Just had to try it didn't you....

Is it even possible for you to walk straight ??

What RPM and what diameter material?Well, this is what 0.080" depth of cut, @0.010"/rev. feed rate.

The material is Uddeholm Impax Supreme (P20 Modified) tool steel, hardened to HB 310. 5" diameter, 250rpm.