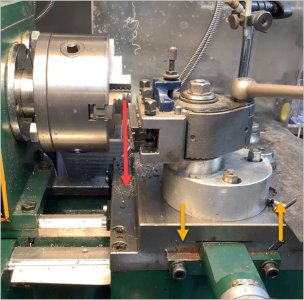

Inspired by the postings of Stephan Gottswinter and Robin Renzetti I made a solid "front" toolpost, rear toolpost and rear compound slide adaption for my 14x60 Mondiale Celtic lathe. I thought it might give others some ideas. I do find that the solid toolposts give a definite advantage with the added rigidity. First pic is the factory setup. The cross slide is secured with the usual two bolts.

Compound with toolpost (I have two of these)

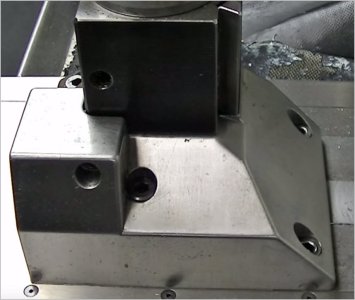

With compound removed. Two small bolts in circular T slot to secure the compound.

Six new nuts with spacers to make it easier to align when mounting solid toolpost, and of course to increase rigidity.

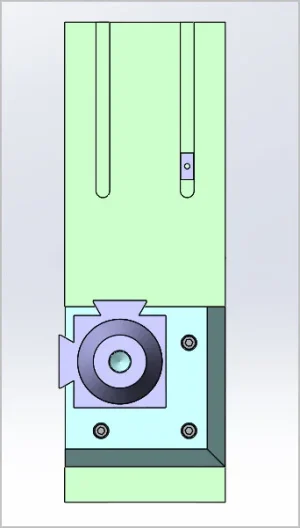

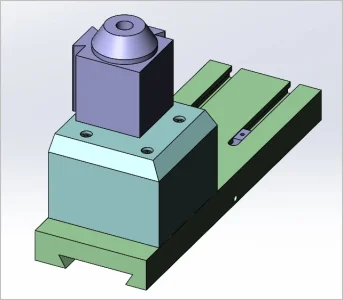

Solid toolpost riser with two locations for mounting toolpost

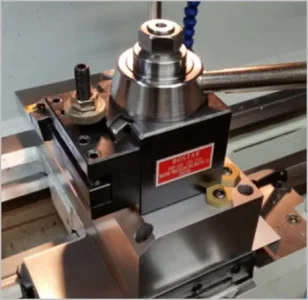

Front riser with toolpost.

Rear toolpost riser.

Rear toolpost riser with toolpost.

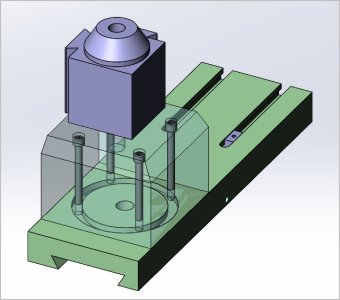

Adapter for mounting compound at the rear. Occasionally there have been times I would have liked to chamfer from the back side of a part. The plate has holes to locate the compound 30 and 45 degrees right and left.

Compound mounted at the rear of the cross slide.

If the Covid does not loosen up soon, I may have to do more damage. The toolposts are Rapid original size A, and I am always on the lookout for more holders if anybody comes across any.

Compound with toolpost (I have two of these)

With compound removed. Two small bolts in circular T slot to secure the compound.

Six new nuts with spacers to make it easier to align when mounting solid toolpost, and of course to increase rigidity.

Solid toolpost riser with two locations for mounting toolpost

Front riser with toolpost.

Rear toolpost riser.

Rear toolpost riser with toolpost.

Adapter for mounting compound at the rear. Occasionally there have been times I would have liked to chamfer from the back side of a part. The plate has holes to locate the compound 30 and 45 degrees right and left.

Compound mounted at the rear of the cross slide.

If the Covid does not loosen up soon, I may have to do more damage. The toolposts are Rapid original size A, and I am always on the lookout for more holders if anybody comes across any.