-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

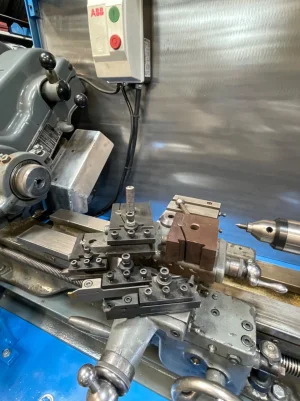

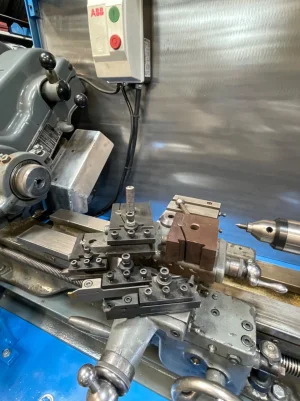

Small quick change tool post

- Thread starter That-Guy

- Start date

I don't quite understand the principle of the curved cut Craig. Is that to tighten the grip on the tool holder in place of the more normal wedge or piston?

Thanks very much @That-Guy for the qctp (and also @trlvn for bring the classified post to my attention).

It actually fits my Myford better than the one I already have.

Here’s my qctp holders:

The mounted qctp and the rust colored one came with the Myford (thanks again @Stuart Samuel). The one on lower left is from That-Guy.

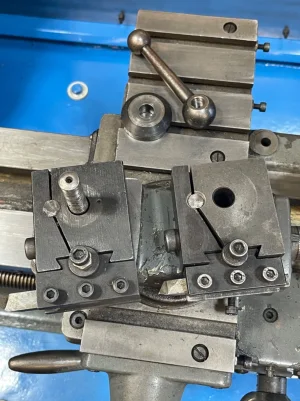

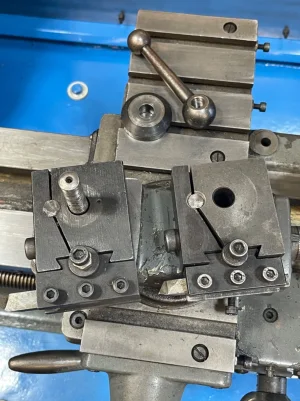

Close up of the two that fit:

The mounting holes are the only differences.

In pic below - The rust colored one has a mounting hole that is 27/64 at the top and reduces to 5/16 for the bottom half and will not fit the Myf. The hole in the one on the right is 1/2”. The one on the left (from That-Guy) has a 29/64 hole and is a nice snug fit. It therefore will be the one I’ll be using. Added plus is that it came with a tool holder so that now I have 4 tool holders.

PS - I’d met That-Guy at the meetup this spring. He’s from the Dunville area. He left the meetup early because a farmer neighbour called and needed some help. He works half an hour from me but he hand delivered the qctp. Guess he’s just a typical Forum member.

It actually fits my Myford better than the one I already have.

Here’s my qctp holders:

The mounted qctp and the rust colored one came with the Myford (thanks again @Stuart Samuel). The one on lower left is from That-Guy.

Close up of the two that fit:

The mounting holes are the only differences.

In pic below - The rust colored one has a mounting hole that is 27/64 at the top and reduces to 5/16 for the bottom half and will not fit the Myf. The hole in the one on the right is 1/2”. The one on the left (from That-Guy) has a 29/64 hole and is a nice snug fit. It therefore will be the one I’ll be using. Added plus is that it came with a tool holder so that now I have 4 tool holders.

PS - I’d met That-Guy at the meetup this spring. He’s from the Dunville area. He left the meetup early because a farmer neighbour called and needed some help. He works half an hour from me but he hand delivered the qctp. Guess he’s just a typical Forum member.

Attachments

Last edited:

The mounting holes are the only differences.

Are those holes not for the stud that clamps the tool post to the compound? If so, all you need is another stud that fits it and your compound. Easy peasy job for any guy who has a lathe....

Yes - but the bottom of the stud incorporates a custom mounting disc. Changing it is not overly difficult but why bother?Are those holes not for the stud that clamps the tool post to the compound?

Yes - but the bottom of thestud incorporates a custom mounting disc.

I think most toolpost studs have that disc.

Changing it is not overly difficult but why bother?

So that you can!!!

Who knows, you may want to make some custom tool holder / tool post interfaces for things like say ...... parting, knurling, etc..... ?