Maybe a bit late & I don't want to make extra work for people. But I thought since this is a metalworking / machinist focus forum, maybe beneficial to start a thread showing '3DP focused' fixtures, tools, accessories etc. you have developed which are useful for typical shop things we do. I'm not opposed to non-developed (downloaded) either if its say a pic with link & price if applicable, but see what others say in that regard. Justification: I've noticed some good stuff is floating in threads with completely different subject titles, so its getting scattered & camouflaged. That really makes my OCD flare up LOL. So endeavor to minimize printer/software specific discussion & chatter unless it pertains to model. Who knows, maybe after a year we will have 500 cool things to look at. I'm not sure if/how sharing model files is practical, leave that thought for now unless someone has some suggestions / instructions?

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tips/Techniques Show your shop related 3DP

- Thread starter PeterT

- Start date

Tips/Techniques

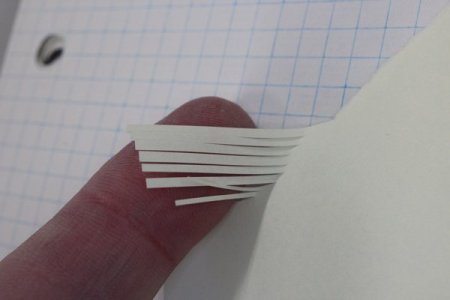

I've been on a profile sanding tool rampage. Probably on the small scale for many of you, but maybe adaptable concept.

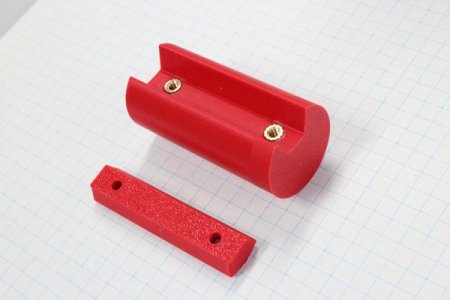

The round one uses stock paper but has an integral clamp so the paper is tensioned to the OD. I use those woodworking carboard core type, but they are generally coarse grit & only nomonal sizes. I wanted something I could load any kind or paper - finer git, wet-o-dry etc. This was a dummy test. I'm making them longer, some progressive diameter increments, tapered...

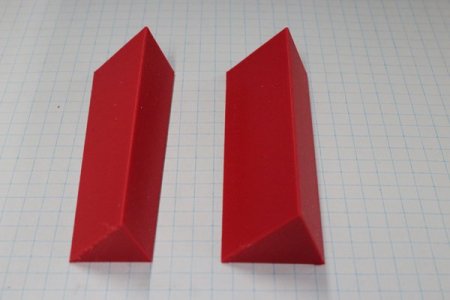

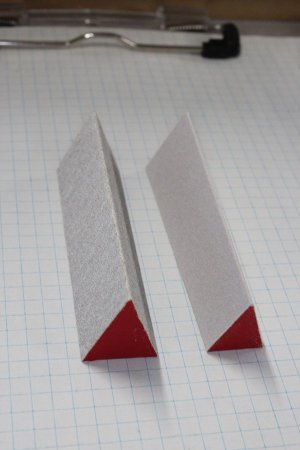

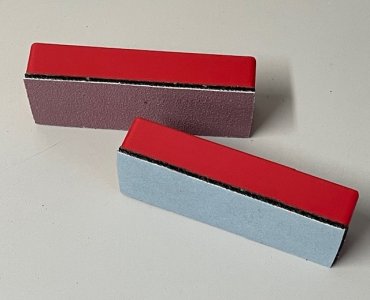

Triangles are self explanatory other than one is tapered which printed just fine. Uses PSA (sticky adhesive) backed sandpaper.

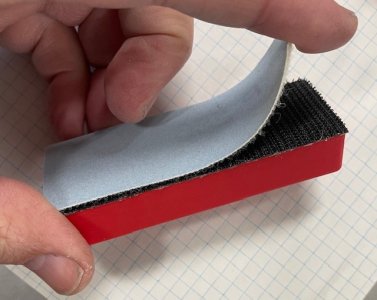

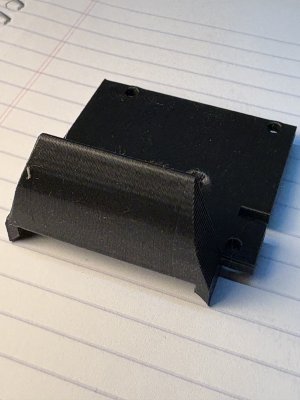

Rectangular are Velcro backed for hook & loop (H&L) sandpaper

About to experiment with backing blocks for light duty touchup work in the lathe, but not sure how successful that would be from a temperature stand point. I suspect the PLA could soften from friction heat?

The round one uses stock paper but has an integral clamp so the paper is tensioned to the OD. I use those woodworking carboard core type, but they are generally coarse grit & only nomonal sizes. I wanted something I could load any kind or paper - finer git, wet-o-dry etc. This was a dummy test. I'm making them longer, some progressive diameter increments, tapered...

Triangles are self explanatory other than one is tapered which printed just fine. Uses PSA (sticky adhesive) backed sandpaper.

Rectangular are Velcro backed for hook & loop (H&L) sandpaper

About to experiment with backing blocks for light duty touchup work in the lathe, but not sure how successful that would be from a temperature stand point. I suspect the PLA could soften from friction heat?

Attachments

Last edited:

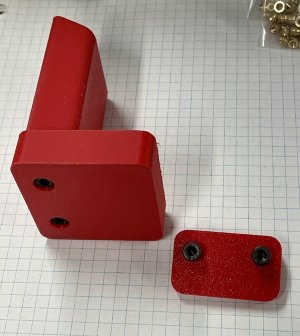

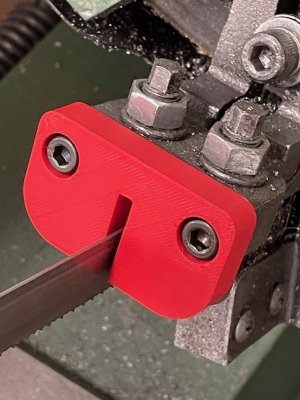

The stamped metal plate that attaches to my drop down saw is (I think?) a glorified barrier to keep shavings piling up around the bearings. That aspect is fine enough, but its an ill-fitting contraption. Its about 3mm stamped metal which requires custom M6 flathead screws. By custom I mean they were buzzed down with a disc grinder at the factory real purdy like. The plate is also too long so it bottoms out on the casting bed & out of adjustment range for shut off switch. So I just jigged the dimensions a bit & this is what you see.

Now that the plate is in position, I started to stare at the blade brush you can see just underneath. So that's the next potential mod. Maybe harvest the ends off a common wire brush & have one on either side of blade which would do a lot to dragging the swarf in behind the pulley cover. Its a bit tight in there but TBC.

Now that the plate is in position, I started to stare at the blade brush you can see just underneath. So that's the next potential mod. Maybe harvest the ends off a common wire brush & have one on either side of blade which would do a lot to dragging the swarf in behind the pulley cover. Its a bit tight in there but TBC.

Attachments

pdentrem

Well-Known Member

Did a bit more on my telescope build today. Worked on the upper section support for the secondary mirror. Did the tension bolts and knobs for same. The SS bolts are cut to length and slotted on the lathe with milling attachment and slitting saw. Cross drilled the bolts with a 0.125” hole and used copper rivet as a pin that holds the SS shim stock. The bolt holes in the uprights will hold the pins in place. 3D printed the knobs with pressed in nuts. Still need to make the attachment for the secondary mirror on the center section at 45 degrees. Enough for today!

Pierre

Pierre

Dan Dubeau

Ultra Member

Cordless drill holders. One more on the printer as we speak.

View attachment 58674

I've made all mine from abs pipe scraps, but like the 3dp idea. One could make integral bit and tool holders to fill in the empty spaces.....Hmmmm

I liked how these fit tightly together. I got the idea when I saw someone selling then for $20 for a 4-unit version on MP.I've made all mine from abs pipe scraps, but like the 3dp idea. One could make integral bit and tool holders to fill in the empty spaces.....Hmmmm

Generic ER collet tray. This happens to be for ER-16 but could work for other sizes as well. I thought about using smaller trays that could be dovetailed together (like the Lego 4 collet holder) but a) Requires a bit more work to develop the locking feature b) Layout considerations. For example if you have 5mm from hole to edge of mini block, then you actually get 5*2=10mm between neighbor holes of adjoining block. This gets further complicated if you want to fit the block assembly inside a box. So it was just net easier to define the tray size by the box dimensions & lay out a hole pattern from that. If I lost you, that's a good thing. It probably means you are not OCD or AR.

Attachments

I don't think I'm OCD, AR probably a bit, at least half right. Where you lost me is you make a lovely, fancy smanchy collet tray.......to fit in a cardboard box ? Hmmm.If I lost you, that's a good thing. It probably means you are not OCD or AR.

I don't think I'm OCD, AR probably a bit, at least half right. Where you lost me is you make a lovely, fancy smanchy collet tray.......to fit in a cardboard box ? Hmmm.

He is just trying to win the cardboard challenge @Janger hosted.

Wrench hooks

Mill power feed control

Tig welder coolant lines block

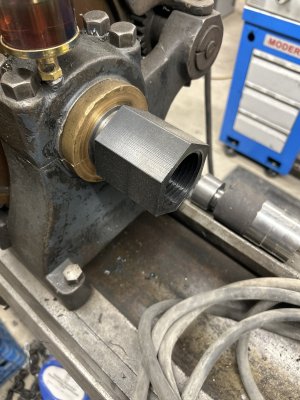

Threaded spindle protectors

Qctp lathe tool holders

ELS control case

Collet holder

CNC mill drive gears, covers, end stops

Mill power feed control

Tig welder coolant lines block

Threaded spindle protectors

Qctp lathe tool holders

ELS control case

Collet holder

CNC mill drive gears, covers, end stops

Attachments

Dang, I missed the contest. No, He has run out of his free supply of common dimension boxes from work so has adopted a new standard. Common boxes stack onto shelves more efficiently than random sized boxes. Ultimately it translates into a higher Stuff : Volume ratio LOL.He is just trying to win the cardboard challenge @Janger hosted.