Now that the stand for my Mill is completed, my next issue is how the splayed feet on the typical shop crane often makes it difficult to lift things. This was a pain when I was moving my lathe, now it's become more of a pain. I haven't decided if I'll actually modify my shop crane as my next project, as I'd prefer to be setting up my Mill. But I can see that eventually it's something that will make it a lot easier to move things around my shop.

I'm interested in opinions on the design I've come up with. What I don't like about my scheme below is that it's much more complicated than I'd like.

My shop is fairly small, so this is the list of requirements:

- The feet can be moved in and out, with a range of 600mm to 1320mm (24" to 52"). 600mm so I can get behind my lathe. 52" so I can straddle a 48" pallet.

- The feet can be moved backwards, so the crane can get closer to loads that are up against a wall.

- It can be pulled apart into pieces which are somewhat flat, so that when it's not in use I can pull it apart and store it under my desk or shelf.

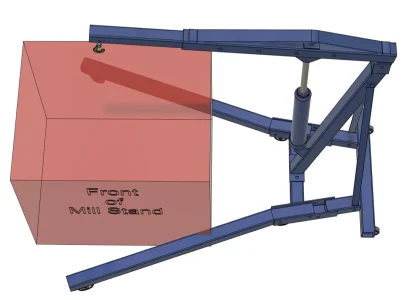

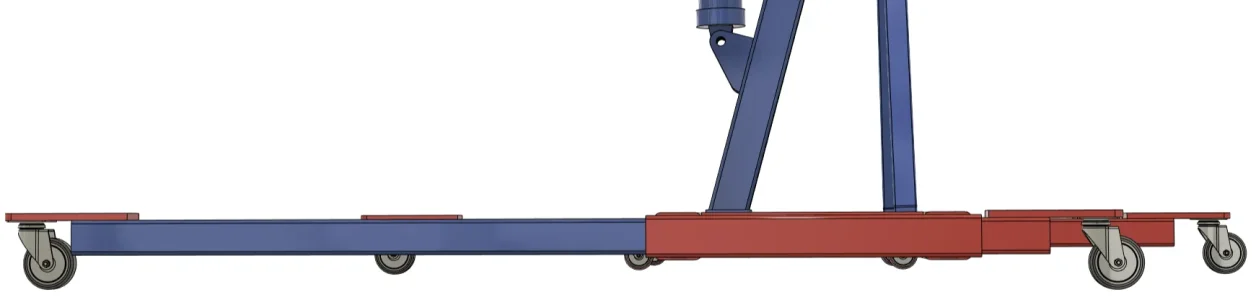

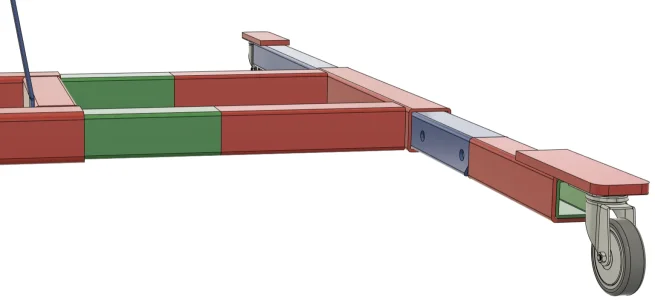

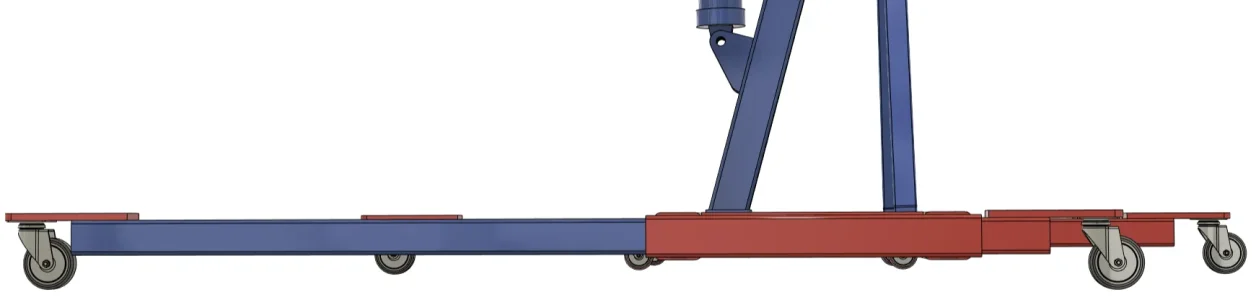

Parts which are a modification of my Princess Auto shop crane are shown in Red or Green.

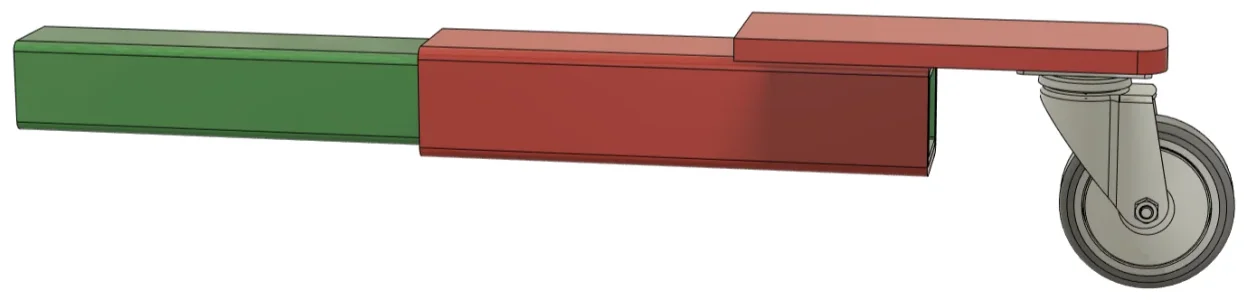

To allow the parts to be stored somewhat flat, I put casters on both ends of the feet. This is a bit of a pain since the feet extensions will need to be removed when storing the crane:

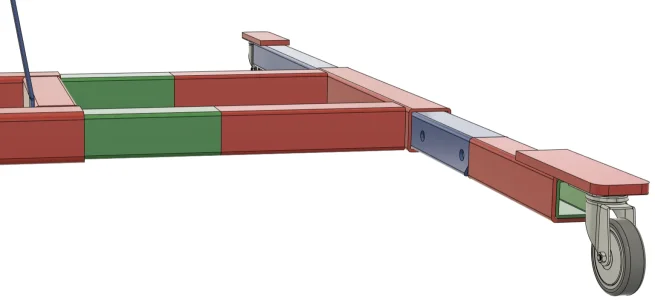

The minimum width is set by the width of the frame, however because this is relatively small it means that multiple sets of extension pieces will be needed to widen the stance to what I think will be my typical width (say 900mm) and then another set to to take it out to 52"- so that's 8(!) extension pieces. At least they'll be easy to make:

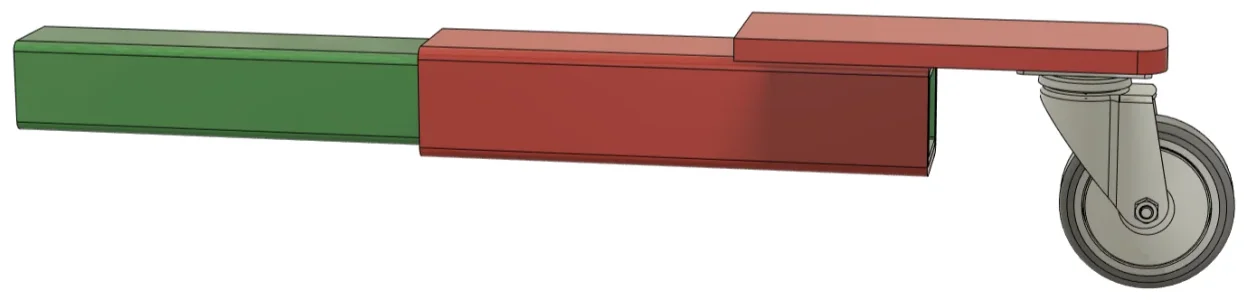

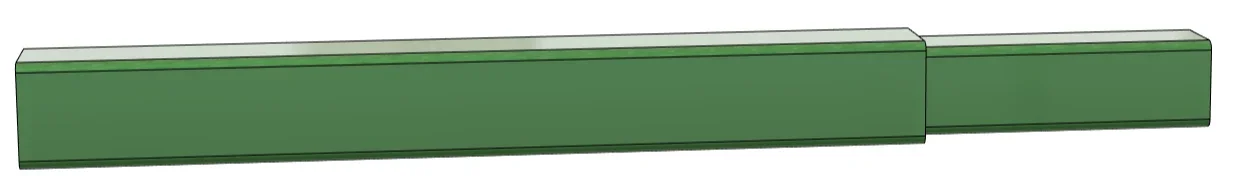

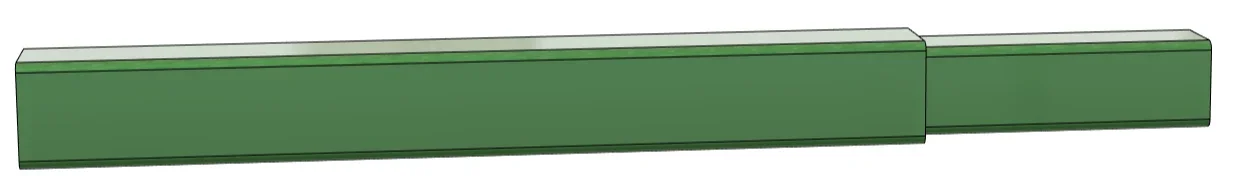

The actual extension piece:

The four wheels on the new base are just for moving the base around when the feet are not fitted. This does mean that to fit the feet, each side will need to be lifted up. Probably also to move the feet backward or forward. In the current design my guess is that about 1/2" of height difference would be about right:

The main casters shown above are a little high, but I didn't model them- just downloaded a model from GrabCAD. I think the casters currently on the shop crane are about the right height(?).

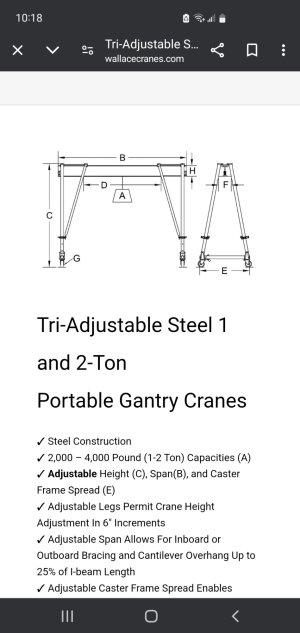

I'd love to have a mobile gantry, but it's another piece of shop equipment that won't be used that often and will need to be pulled apart and stored. So that hope is that a more useful shop crane will largely negate the need for this.

Opinions?

I'm interested in opinions on the design I've come up with. What I don't like about my scheme below is that it's much more complicated than I'd like.

My shop is fairly small, so this is the list of requirements:

- The feet can be moved in and out, with a range of 600mm to 1320mm (24" to 52"). 600mm so I can get behind my lathe. 52" so I can straddle a 48" pallet.

- The feet can be moved backwards, so the crane can get closer to loads that are up against a wall.

- It can be pulled apart into pieces which are somewhat flat, so that when it's not in use I can pull it apart and store it under my desk or shelf.

Parts which are a modification of my Princess Auto shop crane are shown in Red or Green.

To allow the parts to be stored somewhat flat, I put casters on both ends of the feet. This is a bit of a pain since the feet extensions will need to be removed when storing the crane:

The minimum width is set by the width of the frame, however because this is relatively small it means that multiple sets of extension pieces will be needed to widen the stance to what I think will be my typical width (say 900mm) and then another set to to take it out to 52"- so that's 8(!) extension pieces. At least they'll be easy to make:

The actual extension piece:

The four wheels on the new base are just for moving the base around when the feet are not fitted. This does mean that to fit the feet, each side will need to be lifted up. Probably also to move the feet backward or forward. In the current design my guess is that about 1/2" of height difference would be about right:

The main casters shown above are a little high, but I didn't model them- just downloaded a model from GrabCAD. I think the casters currently on the shop crane are about the right height(?).

I'd love to have a mobile gantry, but it's another piece of shop equipment that won't be used that often and will need to be pulled apart and stored. So that hope is that a more useful shop crane will largely negate the need for this.

Opinions?