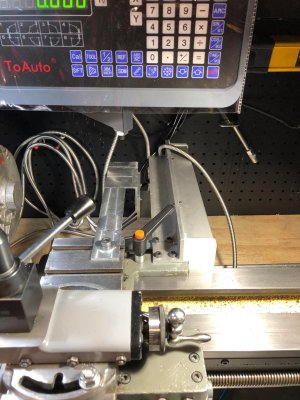

Santa brought me a DRO for my ML7 this year for Christmas. Just finished installing yesterday. Overall it wasn’t too bad. I absolutely love the new level of accuracy and precision it provides. Now I just need to figure out how to use it. I figured out the radius and diameter function - pretty cool…

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Myford ML7 DRO

- Thread starter neer724

- Start date

Santa brought me a DRO for my ML7 this year for Christmas. Just finished installing yesterday. Overall it wasn’t too bad. I absolutely love the new level of accuracy and precision it provides. Now I just need to figure out how to use it. I figured out the radius and diameter function - pretty cool…

Magnetic scales?

Glass is just as good. Just can't be cut to size and takes up more space. Jury is out still on contamination. I'm also concerned about the way I like to use a magnet to clean up chips.Good Morning, no they came with glass scales...

Mine would break just touching it with my shaky hands let alone twisting my tongue wrong.

But good to know it can be done.

They are definitely not any kind of sturdy glass. I was able to fine tune mine to length using needle nose pliers and just crushing the glass. Were I to do it again I would get magnetic scales for their smaller profile.

The 10K might get out fitted one day

The 10K might get out fitted one day

Dan Dubeau

Ultra Member

Well done. A DRO is a great addition to any lathe. I've got a Super 7 and have been wanting a DRO for years. Maybe if I ask Santa nicely he'll bring one for next year.

Inspired by @Xyphota, I decided to redo the y-axis dro scale on the ML7. That huge glass scale hanging off the back of the saddle looked hideous!

I bought a magnetic reader and scale from AliExpress during their 11.11 sale for approx $58 including shipping. The results turned out amazing. Perfect little project on a raining holiday weekend....

I bought a magnetic reader and scale from AliExpress during their 11.11 sale for approx $58 including shipping. The results turned out amazing. Perfect little project on a raining holiday weekend....

Attachments

Tom Kitta

Ultra Member

Glass is just as good. Just can't be cut to size and takes up more space. Jury is out still on contamination. I'm also concerned about the way I like to use a magnet to clean up chips.

I cut my glass scales. Its just more painful to do vs. magnetic, used a band saw for mine. Then drilled and tapped holes for end cups.

I cut my glass scales. Its just more painful to do vs. magnetic, used a band saw for mine. Then drilled and tapped holes for end cups.

The post you quoted is 2 years old. I've learned a lot since then. If I had written it today I would have said:

"Lots of members report good success cutting glass scales. It is low risk. In the two years I've had my magnetic scales, I've not had any problems with chips attracted to the magnetic tape. Magnetic is a bit more compact and the tape can sometimes be directly attached without the need for an additional extrusion to hold it. Glass is less costly. Both perform their intended function equally well."

I think I am going to try and cut my 8 inch glass scale and use it on the mill on the Quill. The built in quill DRO is hard to read and keeps shutting itself off. I currently have the head stock mounted to the z-axis on my mill and figure it is pretty useless as I never machine while lowering the whole head unit. I would use the z-axis for the quill instead....I cut my glass scales. Its just more painful to do vs. magnetic, used a band saw for mine. Then drilled and tapped holes for end cups.

Next weeks project

So - any pointers on cutting the glass scale? I have seen a few youtube vids of people just removing the end cap and stuffing the glass scale with cloth to stabilize the glass and then just use their band saw to cut it. Seems like a disaster waiting to happen but it apparently works....

When I cut mine I just stuck them in the horizontal bandsaw and let ‘er rip. The glass is not tempered and I suspect is not high quality so it just kind of crumbled at the cut like. It was definitely not anything like window glass.I think I am going to try and cut my 8 inch glass scale and use it on the mill on the Quill. The built in quill DRO is hard to read and keeps shutting itself off. I currently have the head stock mounted to the z-axis on my mill and figure it is pretty useless as I never machine while lowering the whole head unit. I would use the z-axis for the quill instead....

Next weeks project

So - any pointers on cutting the glass scale? I have seen a few youtube vids of people just removing the end cap and stuffing the glass scale with cloth to stabilize the glass and then just use their band saw to cut it. Seems like a disaster waiting to happen but it apparently works....

Well that was easy. I pulled the scale apart, pulled the glass scale out. Cut aluminum housing the size, popped it in the mill and cleaned it up. For the glass I wrapped a piece of painters tape around the area to cut, using my dremel with a carbide cutoff wheel and cut it to length. The glass cut really easy with no "burrs".

I put it all back together and tried it - and it didn't work? I thought I might have damaged the read head taking it apart. Then I realized, I might have put the glass in backwards - I flipped it around, put it back together and it worked great!

So if you have to resize your glass scales, it is really not that bad at all....

Now to mount the scale to the mill

I put it all back together and tried it - and it didn't work? I thought I might have damaged the read head taking it apart. Then I realized, I might have put the glass in backwards - I flipped it around, put it back together and it worked great!

So if you have to resize your glass scales, it is really not that bad at all....

Now to mount the scale to the mill