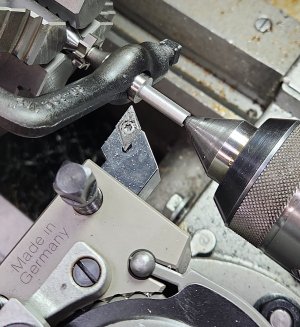

I need to cut a 3/4" t-slot (sort of), very close to a tall vertical wood surface. The endmills I have aren't long enough, and the collet chuck won't let me get close enough. But, I can chuck my ER11 collect chuck in the ER40 collet chuck, and chuck the key cutter. Except the cutter is a 1/2" shank, and the maximum size for ER11 is 1/4".

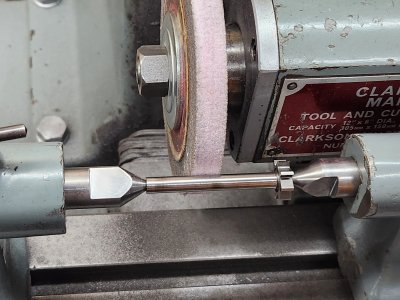

Ok, lets just reduce the shank of the cutter.

Ok, lets just reduce the shank of the cutter.