From a long forgotten Canadian inventor, master mechanic, hobbyist and TSME (Toronto Society of Model Engineers) member (from his private publication) "The Master Mechanics' Manual, Volume One by Le Comte de Millimetres" (George Barrett).

One can make ANY regular or odd size square broach with this method but there is a limit to what thickness one can broach with it (1/8" in mild steel). In desperation, I have made a number of these over the decades mostly in 01 (drill rod) and HSS as I have the grinding equipment to do it.

George doesn't go into a lot of detail in his publication but I will fill in the blanks.

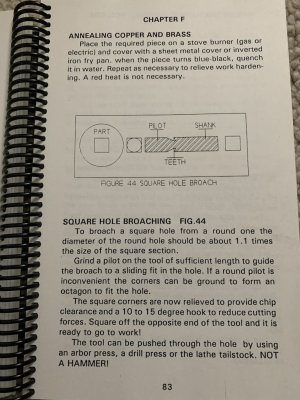

Here it is.

to be continued.

One can make ANY regular or odd size square broach with this method but there is a limit to what thickness one can broach with it (1/8" in mild steel). In desperation, I have made a number of these over the decades mostly in 01 (drill rod) and HSS as I have the grinding equipment to do it.

George doesn't go into a lot of detail in his publication but I will fill in the blanks.

Here it is.

to be continued.